In recent years, with the continuous development of starch sugar industry, sugar alcohols, an important derivative of starch sugar, have also made considerable progress. Due to the special properties of sugar alcohols, their applications are very wide, especially in food, medicine and chemical industry. Among the numerous sugar alcohols, the output of sorbitol is the largest, which occupies an extremely important position in the production of sugar alcohols. Its consumption in the world has exceeded 30%. In the production of vitamin C in the pharmaceutical field, sorbitol is used as the starting material, so far there is no substitute.

At present, sorbitol used in VC production requires high purity, and the traditional process of high purity sorbitol production must use crystal glucose. The reason is that the purity of crystal glucose is high. Only high purity glucose can produce VC grade sorbitol raw material for VC production. However, the traditional process is complex and the cost is high.

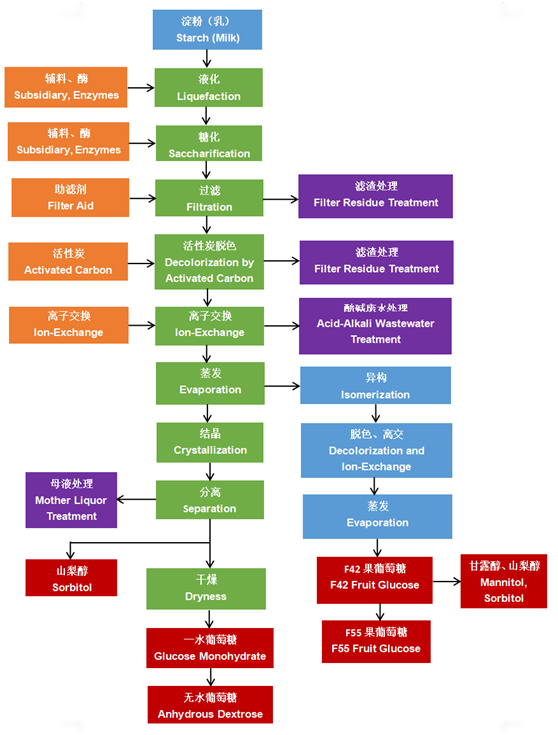

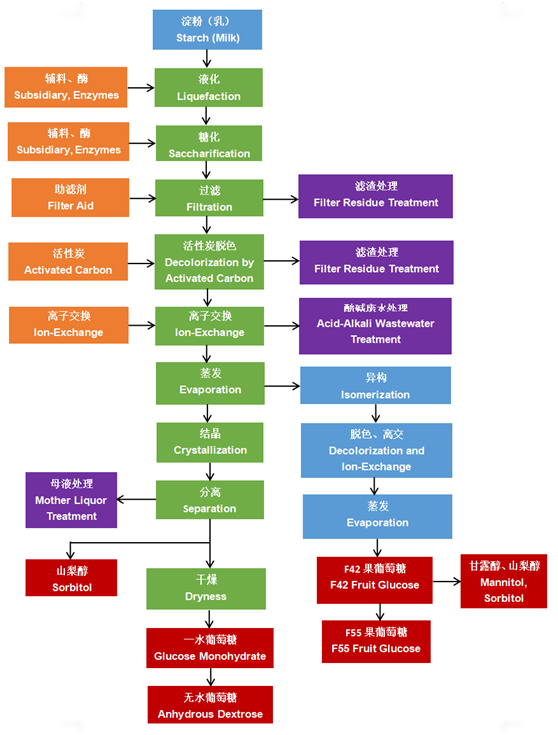

The existing production process of glucose takes starch as raw material, liquefy under the action of liquefying enzyme after refining, and then saccharification by glucoamylase, finally forming glucose syrup with about 95% DX. Then, it is filtered by diatomite in the plate frame or drum to remove the residual starch and suspended solids. Then fixed bed ion exchange process is adopted, in which a large number of anion and cation exchange resins were used to remove the salt in the sugar solution. Finally, high purity glucose was obtained by recrystallization. This production process has the following disadvantages; 1) Resin regeneration needs to consume a lot of acid, alkali and water, at the same time, it will produce a lot of acid-base wastewater; 2) At present, the main end products of glucose are fructose syrup, crystalline glucose and pharmaceutical grade glucose. In order to meet the high purity requirements of pharmaceutical grade glucose, the traditional process can only improve the purity by recrystallization. Therefore, a large number of crystallizers and centrifuges are needed, with large investment and land occupation, and a large number of operators, with low work efficiency and low process yield; 3) On the whole, the traditional production process is batch operation, with low degree of automation, requiring a lot of manpower, and the product quality and yield are relatively low.

Therefore, the production process of high-purity glucose urgently needs a new technology to replace the traditional process in order to improve the yield, purity and efficiency of production.

Fig. 1 Process Flow of Glucose and Its Derivatives

Fig. 1 Process Flow of Glucose and Its Derivatives

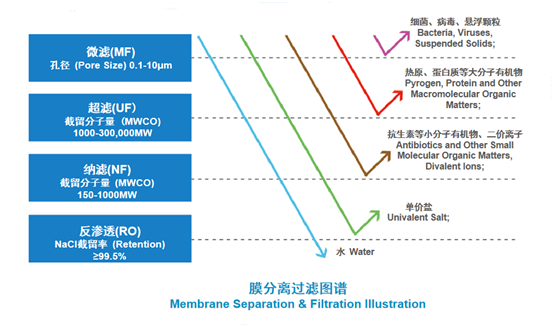

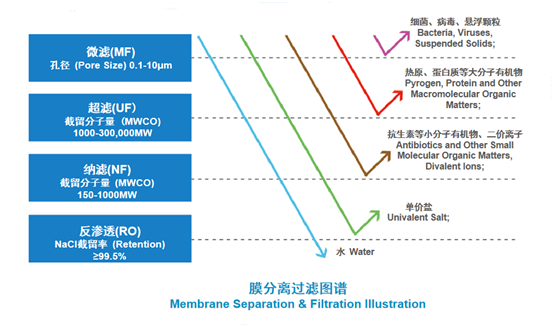

Membrane is a selective barrier between two phases. Generally speaking, it is a kind of polymer, which can selectively separate feed liquid through the effect of pressure difference. The separation process through it is called membrane separation. It is different from the traditional filter in that the membrane can separate materials in molecular sizes, and this process is a physical process without phase change and additional additives. The thickness of the membrane is generally in micron scale. According to filter precision, the membrane can be divided into microfiltration membrane, ultrafiltration membrane, nanofiltration membrane and reverse osmosis membrane. The separation and retention performance of various membranes in cross flow membrane process is distinguished by the pore size and molecular weight cut-off of the membrane. The following figure shows the separation patterns of four kinds of membranes with different precision (the reflection of the arrow indicates the retained substances which cannot pass through the membrane).

Fig. 2 Membrane Separation & Filtration Illustration

Fig. 2 Membrane Separation & Filtration Illustration

The traditional production process uses crystallization and recrystallization to improve the purity of glucose to obtain high-quality glucose. This process has many disadvantages, such as: backward process, high cost, huge pollution, inconvenient operation, unstable product quality, which cannot meet the quality requirements of customers. Therefore, in recent years, new technologies and processes for innovation and transformation has continuously been introduced in the industry. Guo Chu Technology (Xiamen) Co., Ltd. is committed to the research and development of this process, and has developed and formed a brand-new process: Membrane Filtration for Saccharified Liquid → Continuous Ion-Exchange Desalination → Nanofiltration Purification, which achieves the 24-hour continuous operation of the whole process, and has the following advantages: advanced technology, low cost, little pollution, full automation, and with the product quality which is not only stable, but also could reach the highest level in the industry at present.

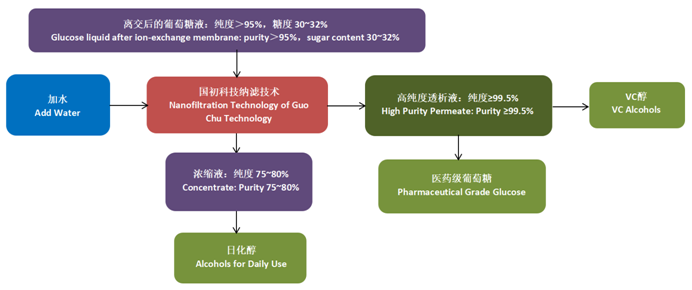

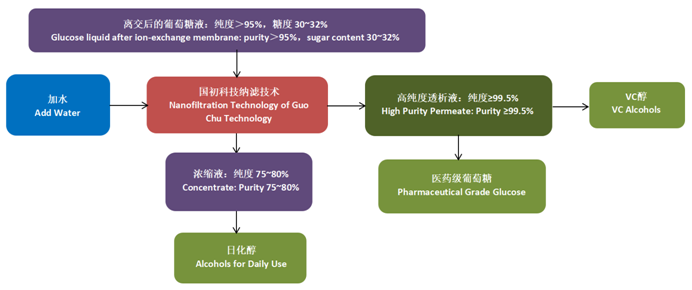

Fig. 3 Process Flow of Glucose Refining Membrane

Fig. 3 Process Flow of Glucose Refining Membrane

This process is verified and designed in combination with the mature industrial application of the project of separation and purification of similar sugars. The feed liquid is deliming solution after ion-exchange membrane, with a general purity of more than 95% and a sugar content of 30-32%; After being separated by nanofiltration technology of Guo Chu Technology (Xiamen) Co., Ltd., the high purity permeate with purity ≥ 99.5% can be used to produce VC grade sorbitol or pharmaceutical grade glucose solution; However, the purity of glucose in concentrate of membrane is relatively low, with a purity of 75-80%, which is used to produce alcohols for daily use.

The new membrane filtration technology of Guo Chu Technology (Xiamen) Co., Ltd. is used to prepare glucose solution with purity of nearly 100%. High purity sorbitol liquid is produced by catalytic hydrogenation without crystallization. The production process is simple, the flow path is short, and many procedures are saved compared with the traditional process. The large-scale industrial production shows that the product quality is better than that of the traditional process, the production cost is low, the product yield is high, and there is almost no pollutant emission. At the same time, the water consumption is greatly reduced, and the clean production is really achieved.

Guo Chu Technology (Xiamen) Co., Ltd. is a high-tech enterprise, which focus on membrane separation technology and is committed to the promotion of new separation technology. It provides comprehensive filtration and purification solutions for many industries, such as bio-pharmaceuticals, food & beverage, fermentation, agricultural deep-processing, plant extraction, oil and petrochemical industry, environmental water treatment, air de-dusting, chemical industry etc to meet the diversified demands of different customers, and is a well-known integrated service provider of new separation technology.