Milk is one of the favorite foods in people’s daily life, and the advantages of drinking milk now are increasingly recognized by the public, and with very complex chemical compositions, it has been proved that there are at least 100 multiple chemical components in milk, mainly including fat, protein, lactose, vitamin, enzyme and inorganic salt. Milk has rich calcium, vitamin D and other substances, including all amino acids required for human growth and development, and the digestibility is as high as 98%, so that other foods can’t be comparable with it. At present, the most common milk is whole milk, low-fat milk and evaporated milk. There are quite a few milk additives in the market, for example, high calcium and low-fat milk emphasizes that it has calcium added.

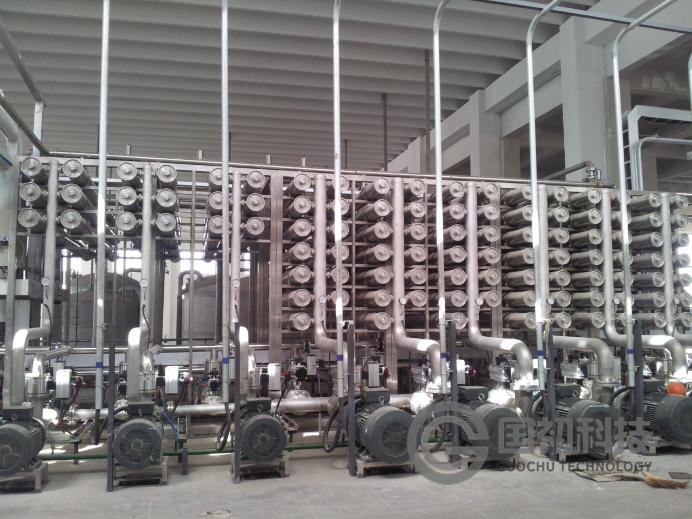

Membrane separation technology has been used in dairy industry for many years, and its application in food industry is second only to the beverage industry. The application of membrane technology in food industry in foreign countries begins with dairy processing. Because the membrane separation technology has less environmental pollution and low energy consumption, and it avoids the thermal damage of products without the use of additives and filtration colleagues separate it from material concentrated goods, it shows more and more practical value and broad application prospect in dairy processing.

The application of membrane separation technology in dairy industry can simplify production process, reduce energy consumption, reduce wastewater pollution and improve the comprehensive utilization rate of dairy products. At present, the application of membrane technology in dairy industry mainly includes: milk sterilization and concentration, standardization of dairy foods, milk protein concentration, whey recycle and whey processing and utilization and wastewater treatment.

Most of whey liquids are cheese production by-products, which contain high quality protein and whey protein and are easy to be absorbed by infants and young children. However, the whey liquid has high salt content and high salt content, which cause damages to infant kidneys, so it should carry out desalination, lactose removal and other standardized processes. Therefore, the organic combination of membrane separation technology, electrodialysis technology and ion exchange technology has complementary advantages and avoids its disadvantages, so it can effectively reduce the operation cost of desalination, reduce the amount of waste liquid, recycle whey protein and lactose and produce D90 demineralized whey powder.

Advantages of membrane technology applied in dairy industry:

Contact:

Tel:+86 592 6514970

Email:market@guochukeji.com

Skype:18060902001

WhatsApp:18060902001

WeChat:18060902001

TM: guochukeji

QQ:1641011431