Ultra-clean and high-purity chemicals are essential basic chemical materials in the development of microelectronics technology. They are mainly used in the fields of semiconductors, flat panel displays, and solar photovoltaic industry, as well as microelectronics and optoelectronic device manufacturing. With the rapid development of microelectronics technology, the requirements and standards for ultra-clean and high-purity reagents are constantly improving. The purity and cleanliness of ultra-clean and high-purity chemicals can significantly influence the yield, electrical property, and reliability of integrated circuits. The production process technology of integrated circuits (IC) with different line widths also has different standards for metal impurities and particulate matter in ultra-clean and high-purity chemicals, as shown in the following table:

SEMI International Standard Grade and Application

|

SEMI standard |

Grade 1 |

Grade 2 |

Grade 3 |

Grade 4 |

Grade 5 |

|

Metal impurity |

≤1ppm |

≤10ppb |

≤1ppb |

≤100ppt |

≤10ppt |

|

Partical size control |

≤1.0μm |

≤0.5μm |

≤0.5μm |

≤0.2μm |

/ |

|

Particle control |

≤25pcs/ML |

≤25pcs/ML |

≤5pcs/ML |

/ |

/ |

Scope of application

(IC technology production) |

≥1.2μm |

0.8-1.2μm |

0.2-0.6μm |

0.09-0.2μm |

≤0.09μm |

|

Application |

Discrete device, solar cell |

Display panel |

Large scale integrated circuit, ultra-high definition display panel |

Large scale integrated circuit, ultra-high definition display panel |

|

Ultra-clean and high-purity chemicals accompany the entire production process of integrated circuits. In the wet process, metal impurities in the chemicals can harm the electrical property of electronic components, even a very small amount of metal impurities will seriously affect the quality of semiconductor products. Take Au, Pt, Fe, Ni, and Cu for example, they are fast diffusing substances in silicon wafers that can affect the reliability and threshold voltage of electronic components and may lead to low breakdown and defects. Alkali metals such as Na and K can melt into the oxide film, causing electric leakage of components and low breakdown hazards. P, As, Ab, and Al are shallow level impurities in silicon wafers, which have diffusion effect and can affect the number of electrons and holes. With the increasing integration of integrated circuits, the requirements for metal ion content in ultra-clean and high-purity chemicals are becoming more and more strict.

At present, the commonly used technologies at home and abroad to prepare ultra-clean and high-purity reagents mainly include distillation, rectification, resin exchange, recrystallization, chemical treatment, membrane processing, and some other technologies. The membrane processing technology is a physical separation process that does not require heating or adding any chemical reagents, and it is an effective way to remove trace metal ion impurities. Based on years of experience in membrane technology application, Guochu Technology has developed a process for removing metal ions from ultra-clean and high-purity chemicals.

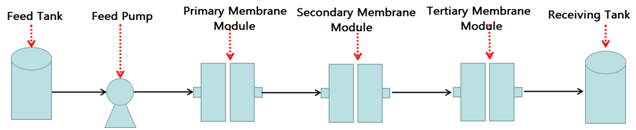

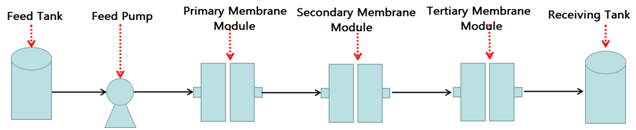

Technological process:

In order to avoid the contamination of the dissolved matter of the contact parts, the contact parts with ultra-clean and high-purity chemicals in the technological process should be made of high-purity materials. The primary membrane module can reduce the metal ion impurity content to ppb level, the secondary membrane module can reduce the metal ion impurity content to ppt level, and the tertiary membrane module is the terminal filtration to ensure that the solvent is free of particles, with an accuracy of up to 5 nm. This process has a good removal effect on metal impurities such as K, Na, Ca, Cu, Fe, and Mg.

Compared with the traditional distillation process, this process has the advantages of a small footprint, easy-to-operate, sealed system, low energy consumption, and is environmentally friendly. It can be used not only in the production of ultra-clean and high-purity chemicals, but also in the purification of other high-purity reagents in the semiconductor manufacturing process, such as resins, polymers, and other photolithographic chemical products.

Since the establishment of Guochu Technology (Xiamen) Co., Ltd., we have taken membrane separation technology as our core and are committed to promoting new separation technology. We continuously explore new applications of the new separation membrane technology in the fields of microelectronics, metallurgy, chemical industry, machinery, food, dairy, beverage, and environment.We can provide targeted comprehensive filtration and purification solutions and improve the product quality to meet the highly differentiated needs of our customers.