Phosphoric acid is mainly applied in pharmaceutical, food, fertilizer industries, used as rust inhibitor, food additive, EDIC corrosives, electrolytes, fluxes, dispersants, industrial corrosives, raw materials for fertilizers, dentistry and orthopedics products and household cleaning products. Phosphoric acid can also be used as a chemical reagent. And phosphate is a nutrient for all life forms.

The production of phosphoric acid mainly includes thermal process and wet process. Thermal phosphoric acid is mostly used in the chemical and food industries, but its production process consumes high energy, complex equipment and serious pollution. With the requirements of economic development for energy saving and environmental protection, the phosphoric acid production process has gradually replaced the thermal method with high energy consumption and high pollution by the wet method with low energy consumption. The output of wet-process phosphoric acid in the world accounts for about 85% to 90% of the total output of phosphoric acid. However, in the production of wet-process phosphoric acid, the impurities in the raw phosphate rock, such as fluorine, sulfur, iron, aluminum, magnesium, calcium, etc., enter the finished phosphoric acid. Therefore, if wet-process phosphoric acid is used to produce high-quality phosphate products, the impurity ions must be thoroughly purified.

The primary methods for removing ions in wet-process phosphoric acid include: solvent precipitation, solvent extraction, ion exchange, and cooling crystallization.

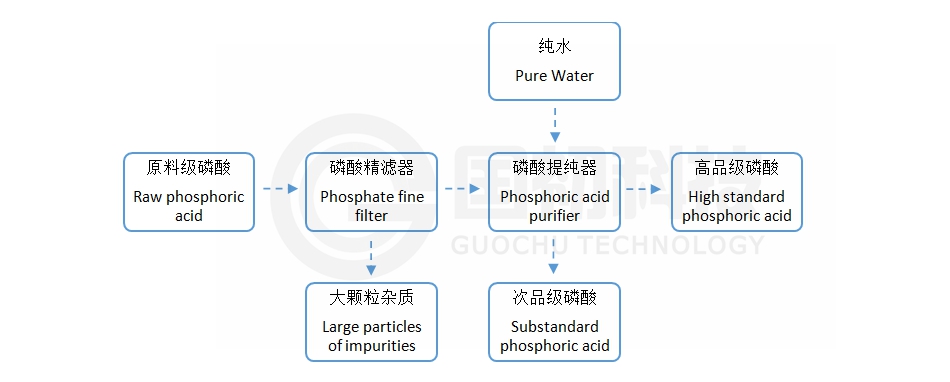

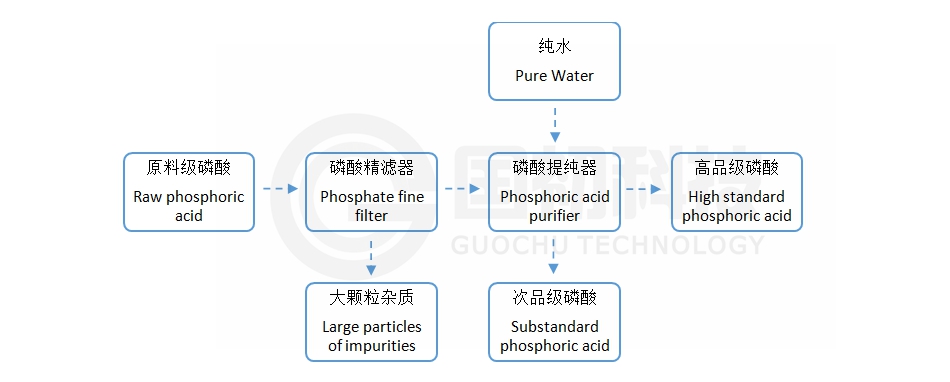

Both the solvent precipitation method and the solvent extraction method need to add a solvent, which increases the processing steps and the energy consumption of solvent recovery. The ion exchange method requires a large amount of resin and high production cost. The cooling crystallization method has a low product yield and demands multiple crystallizations to obtain high-purity phosphoric acid. Guochu Technology utilizes the characteristics of membrane separation technology to successfully develop phosphoric acid purification technology. The physical method of membrane separation is used to remove pollutants without phase inversion, thereby reducing operation time, energy consumption and equipment footprint, and improving phosphoric acid purification efficiency.

In response to different conditions, Guochu Technology (Xiamen) Co., Ltd. successfully developed a new type of phosphoric acid purification technology.

Features and advantages:

1. It is suitable for the purification of phosphoric acid with high acid concentration and high ion impurity content.

2. In the process of phosphoric acid purification, there is no need to heat or pressurize, which is safe and reliable, having extremely low energy consumption.

3. Competitive phosphoric acid recovery rate and the recovered phosphoric acid concentration.

here are many types of impurities in wet-process phosphoric acid. Feed grade, food grade, industrial grade, etc. have different requirements for the quality of phosphoric acid. Different purification methods can be selected according to actual demand. If a single purification method cannot meet the requirements for the purity of phosphoric acid, two or more purification technologies can be combined, taking advantage of the various features of different purification technologies. In addition, with the development of the microelectronics industry, the demand for high-purity electronic grade phosphoric acid will also increase. Guochu Technology will continue to explore new technologies for the purification of higher purity phosphoric acid.

In addition to phosphoric acid purification, Guochu Technology's acid purification technology can also be used for the recovery and purification of various waste acids such as hydrochloric acid, nitric acid and sulfuric acid, providing strong technical support for the waste acid treatment of enterprises.

Guochu Technology (Xiamen) Co., Ltd. is continuously committed to the promotion of new separation technologies. We have rich experience in special membrane applications in the pharmaceutical, chemical, food, beverage, petroleum, petrochemical, and nuclear energy industries. With the ability of R&D, we can develop technology and equipment that meet different specific requirements, according to customer demand.