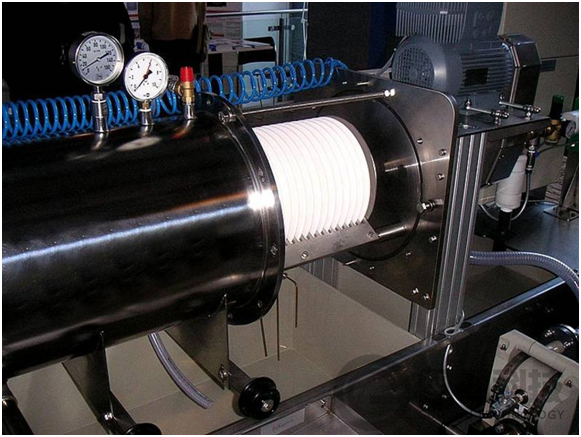

Centrifugal Membrane filtration is a kind of new separation utilization in membrane filtration technology, by dynamic whirling of membrane modules to accomplish alleviation of membrane pollution. Telling from its structure, its hollow axle spins driving leaves (in disc form fixed central-through-axial) rotating along with it. When membranes are high-speedily swirling with the axis by motor empowered driven force, centrifuge and shear force along with the dynamic turbulence of the filtered liquid caused by the rotating movement could high-effectively cleanse the membrane filtrating layer, eliminate the concentration polarization on membrane surface, where membrane permeability decays slowly and not easily influenced to raw liquid concentration, continuous and stable filtering period lasts long; Meanwhile the technology reduces salt crystallization, fouling, gel-layer, organics and so on contamination, largely expands the chemical wash period of the filtering membrane; And the system does not require very high flow or pressure, hugely saving the energy consumption, the electricity taken merely occupies one third of the tubular ceramic membrane.

Centrifugal Membrane Device successfully combines the mechanisms of centrifugal separation and cross flow filtration . Not only It equips nano-scale filtering precision but also makes stable operating performance certainly and brings with brilliant energy-saving effect. The system runs without relying on feed pump providing large flow volume circulation but inner swirling motion to achieve results of separation and filtration of raw liquid. Compared with traditional cross flow method, the rotation structure divides flow into high to low graded concentration by centrifuge force, through different line speed of the inner and outer circle supplying to different centrifuge force to treat the pollutants. Centrifugal filtration could enhance the permeability which makes filtration more efficient, circles of concentration higher, detainments more condensed, product yield higher, water-adding less and energy consumption lower.

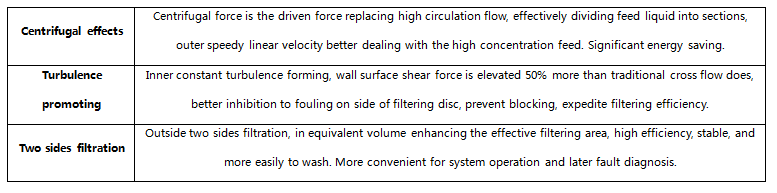

Centrifugal Membrane:

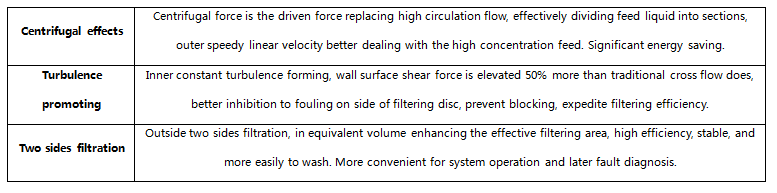

It is the core element of separation process, the contour is shaped round or square, the membrane embraces two sides of separating layer with inner flow direct channel, the central surrounding equipped several liquid discharge holes, feed liquid pass through outside to inside when filtering. The disc material is often made of inorganic material or organic material. The filtration precision ranges from microfiltration and ultrafiltration to a series of molecular weight, specific listed in category of 2µm, 0.5 µm, 0.2 µm, 60 nm, 30 nm, 7 nm, 5 nm, 100KD, 50KD, 30KD, 20KD, 10KD, 5KD, 1KD, etc. Inorganic membrane is characterized with its strong chemical durable property as well as heat-resistant property, backwash available; Organic membrane acts of extremely fine filtering precision, suitable in every aspects of separation and purification.

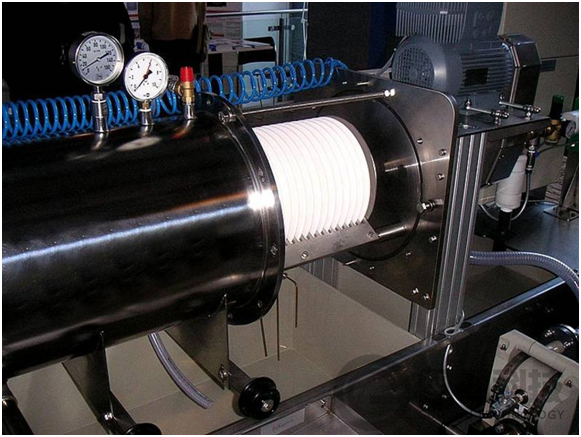

Centrifugal Membrane Module:

To install the centrifugal membranes cross a hollow axle central-through, each other sealed by “O” seal ring, the whole body placed in a pressure container, the membrane module is done. According to the varies of anti-pollution property and heat-resistant property, the pressure container normally selected as stainless steel, fiber reinforced plastic and engineering plastic.

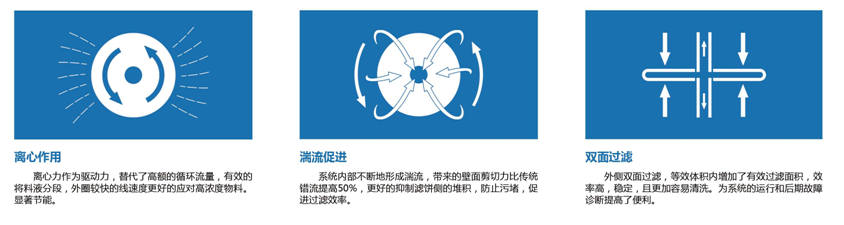

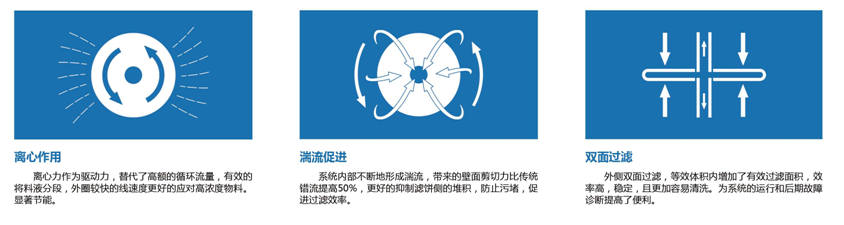

Centrifugal Membrane Advantages:

|

-

Easy to wash: easy to wash and recovery

|

-

Flexible: flexible modes design, further installation proclined, easy to check and maintain

|

-

Concentration multiple high: Less residue and save cost for latter evaporation and dry

|

-

Convenient: small device occupation, automotive elevated module housing, install and displace membrane disc without difficulty

|

-

High-efficiency: innovative dynamic cross-flow technique enhances the flow treatment, time saving and productivity booming, high heat resistant

|

-

Filtering liquid of good quality: turbidity drops to 1NTU below, no plus additives, filtering quality secured, unopened pressure adjustment to avoid air oxidation

|

-

Energy saving: specialized system design play flow rate absent from large flow circulation pump supply, facile energy saving to 60%-80%, anti-pollution and easy cleaning

|

-

Improved process: low pre-treatment requirement, high concentration multiple, system replacing multiple process steps, strong function and save investment, long service term

|

-

Durability: resilient anti-pollution property, facile fixing harsh fluid, anti-acid/base, organic solvent resistant, utmost durable viscosity to 7000 mPas

|

Centrifugal Membrane Application:

|

|

|

Nano-Powder Wash |

FePO4/Li3PO4 Wash |

|

Ink Wastewater Recycling |

Dairy Protein Concentration |

|

Pectin Concentration and Filtration |

Montmorillonite Concentration |

|

Red Wine Clarification and Filtration |

Emulsion Wastewater Treatment |

|

Fruit Juice Clarification and Filtration |

Beer Clarification and Filtration |

|

Egg Liquid and Egg White Concentration |

Filtration of Brewing Condiments |

|

Filtration of Antibiotic Fermentation Broth |

Carbon Nanomaterial Purification |

|

Wash Water Treatment of Vessel Sulfur Reduction |

Biogas Liquid Concentration and Filtration |

|

Graphene Acid Reduction and Elution Treatment |

Electrolyte Filtration and Impurity Removal |

|

Oil Concentration from Oil-Contained Wastewater |

Polysaccharide Concentration and Filtration |

|

Enzyme Preparation Impurity Removal and Filtration |

Chinese Medicine Alcohol Extracting-Water Precipitating Filtration |

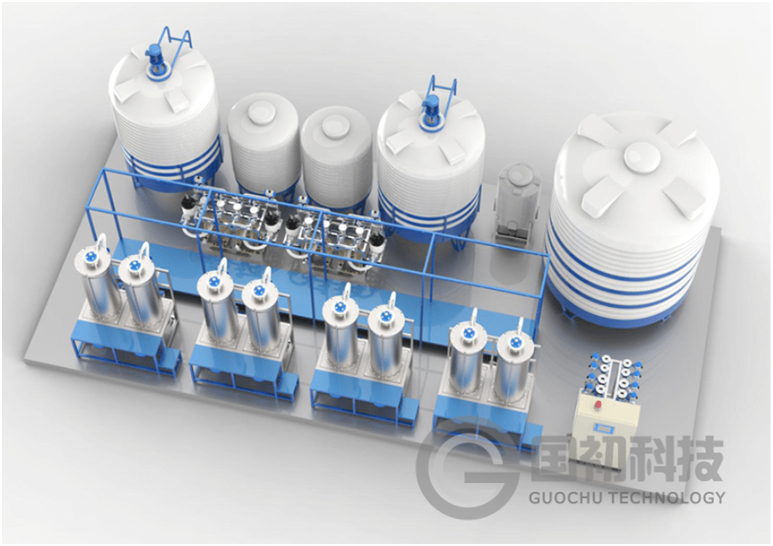

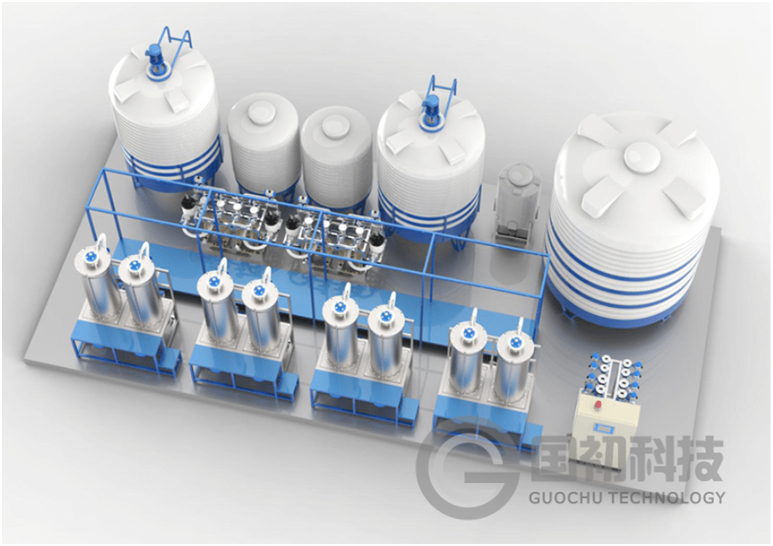

Guochu Technology (Xiamen) Co., Ltd provides every scale centrifugal membrane, centrifugal membrane module, centrifugal membrane lab equipment and centrifugal membrane industry equipment, please contact us for information of specific applications and technical problems.