The ceramic membrane is a porous fine ceramic filter which is sintered from Aluminia, Titania or Zirconia under ultra-high temperature. Ceramic membrane normally has an asymmetrical structure with porous support active membrane layer. The macro porous support ensures the mechanical resistance while the active layer functions separation ranging from Microfiltration, Ultrafilatration and even Nanofiltration.

Ceramic Membrane always runs at a CROSS FLOW FILTRATION mode. The turbid fluid goes through the membrane layer inside a single-channel or multi-channel at a high velocity. Driven by pressure, the clean liquid with micro-molecule passes through the membrane layer vertically to permeate, the solid and big molecule is retained. The feed liquid is thus clarified, concentrated and purified.

Compared with normal traditional filters like Filter Press, Centrifuge and DE Filter, ceramic membrane filters have many unique advantages:

-

Excellent resistance to acid/alkaline and oxidation chemicals

-

Solvent stability

-

High thermal stability

-

Fine separability with narrow pore size distribution

-

Excellent mechanical and abrasive resistance

-

Extremely long work life

-

l The compact multi-channel geometry and high permeability are optimized for bulk processing applications.

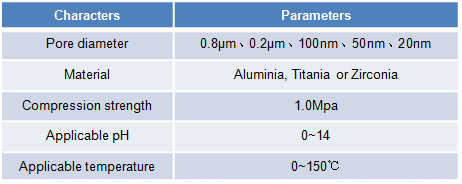

Technical Data of Membrane

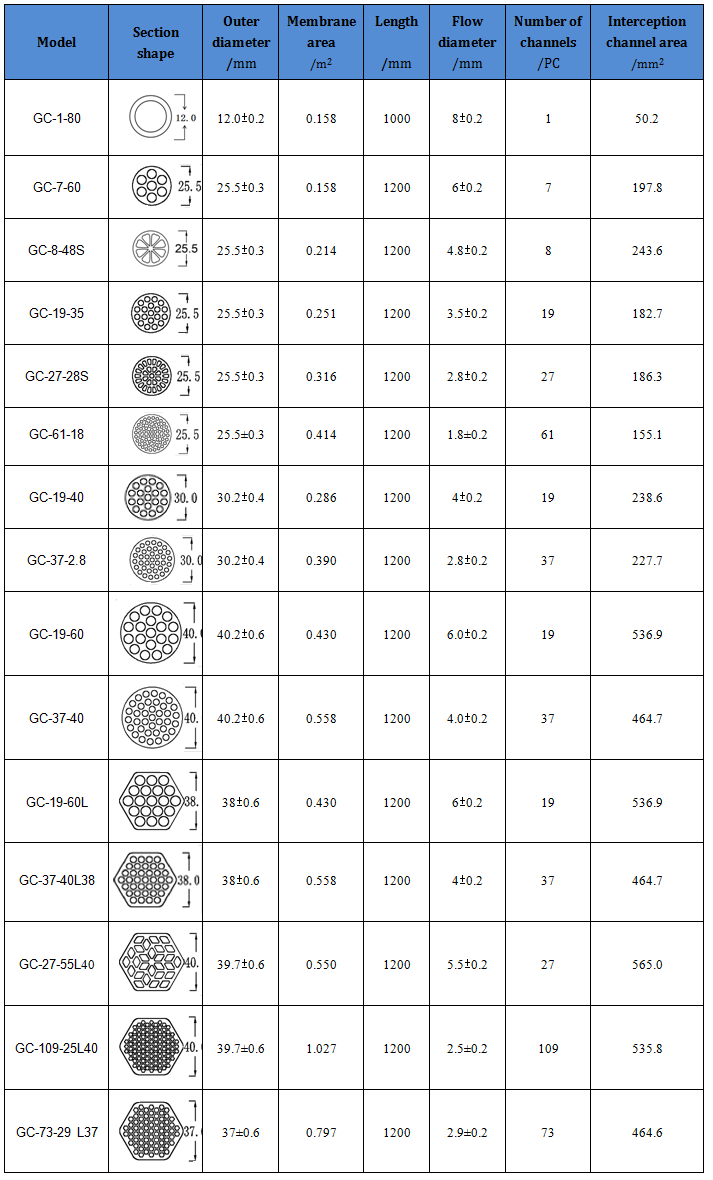

MEMBRANE MODULE

A housing filled with ceramic membrane elements is called ceramic membrane module. Based on the demands, the modules can be different. It is available to combine different OD or area of ceramic membrane elements together into one module. The design of outline and sealing type of Ceramic Membrane Module is significant, for the whole system operation.

A complete range of modules helps for scale-up from laboratory separations to full size industrial needs.

Experimental equipment:

A complete range of modules helps for scale-up from laboratory separations to full size industrial needs.

Experimental equipment:

Small scale equipment :

Small scale equipment :

Large scale equipment :

Large scale equipment :

For the further information on Ceramic membrane products, please do not hesitate to contact our technical service team. Looking forward to long-term cooperation.

Contact:

Tel:+86 592 6514970

Email:market@guochukeji.com

Skype:18060902001

WhatsApp:18060902001

WeChat:18060902001

TM: guochukeji

QQ:1641011431