Products for Membrane Filtration

The Right Membranes and Modules for a Multitude of Applications

Customers, plant manufacturers and engineering companies from all over the world are using our

membrane products. For us this is a reliable indication for their confidence, trust and faith in our company and products.

Membranes and modules for the water Filtration and wastewater treatment

During the last 50 years MICRODYN-NADIR gathered its customers´ trust with hard work and innovative membrane products like the BIO-CEL

® module as well as with superior quality

Membrane Bioreactor (MBR) technologies, like our BIO-CEL

® MCP (Mechanical Cleaning Process). Moreover, we are a well-known and successful manufacturer of durable modules for industrial applications in markets, such as the Pharmaceutical, the Chemical and the Food & Beverage Industry.

In order to ensure the highest quality and superior product performance, MICRODYN-NADIR ascertains its products´ reliability and integrity for the manufacturing and application process already at the research and product development stage.

A wide range of membrane and module configurations for water- and wastewater treatment

MICRODYN-NADIR products are designed for different pressure-driven processes, such as crossflow, semi-and dead-end operation. We deliver high quality membranes based on:

·

Polypropylene (PP)

·

Polyethylene (PE)

·

Polyethersulfone (PES)

·

Polyacrylonitrile (PAN)

·

Polystrene (PS)

·

Polyvinylidene fluorid (PVDF)

·

Regenerate Cellulose (RC)

High quality standards for safe water-and wastewater treatment

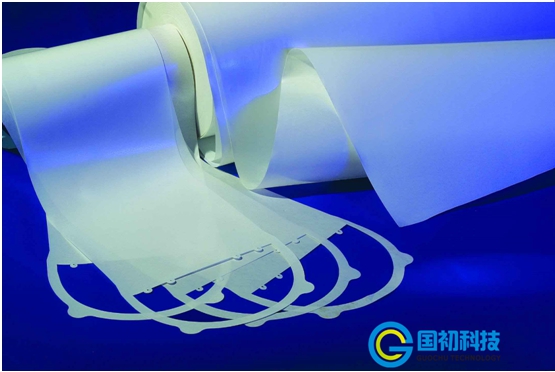

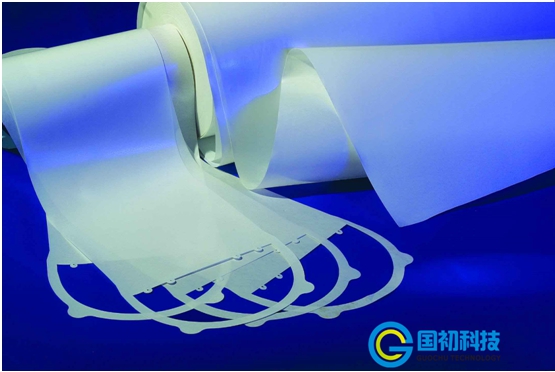

NADIR® Membranes

Membranes and Formats for Filtration Challenges

For more than 50 years MICRODYN-NADIR has been manufacturing flat sheet membranes in one of Europe's largest membrane production facilities for municipal and industrial applications.

NADIR

® membranes are permanently hydrophilic and chemically resistant. The NADIR

®membranes are produced with the highest quality and consistency in a specially developed process.

Chemically resistant and hydrophilic flat sheet membranes made of different polymers

The results speak for themselves: the unequalled

hydrophilic properties of NADIR

® membranes increase performance, longevity and significantly reduced fouling. NADIR

® membranes are available with cut-offs covering the spectrum of micro-, ultra- and nanofiltration applications.

NADIR® membranes are available in a range of polymeric materials:

· Polyethersulfone (PES)

· Hydrophilic Polyethersulfone (PESH) and Polysulfone (PSUH)

· Regenerated Cellulose (RC)

· Polyvinylidenefluoride (PVDF)

These materials can be used in a wide range of applications.

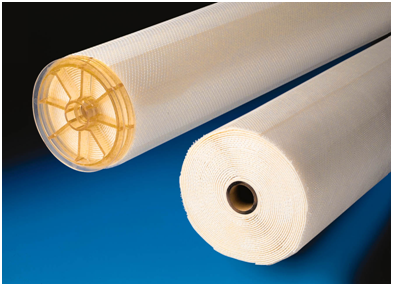

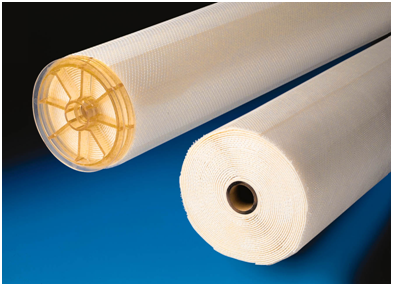

SPIRA-CEL® Spirals

Membrane Filtration with Spiral Wound Modules based on NADIR® Flat Sheet Membranes

Spiral wound modules have a great variety of potential combinations and consequently this module type is the most common installed in filtration plants. They are used in applications ranging from the beverage, food and the pharmaceutical industry to environmental and biotechnological processes. The modules are used to separate particles like colloids, proteins and micro-organisms and to decontaminate fluids.

SPIRA-CEL® spiral wound modules – compact design

SPIRA-CEL

® spiral wound modules are available with all types of NADIR

® membranes (microfiltration, ultrafiltration, nanofiltration). They have a compact design and offer an optimum surface-area-to-volume-ratio.

The feed channel height can be varied by the thickness of the spacer material (from 30 to 80 mil). This allows to adapt to different levels of solids content of the liquid. This design feature leads to excellent hydrodynamics in combination with low energy demand.

A variety of module configurations for different applications

SPIRA-CEL

® spiral wound modules have an outstandingly high stability against temperature and pH. They can be used to

clean both caustics and acids. They can also be used in biotechnological applications where extreme cleaning conditions are required.

In addition to the commercialized SPIRA-CEL

®-OX type modules (pH range of 3-14, and operational temperature of 80 °C) SPIRA-CEL

®-OY type modules are also available with a pH range of 0 -12 and operational temperature of 80 °C. These module types are offered with polyethersulfone membranes in microfiltration, ultrafiltration and nanofiltration ranges.

MICRODYN-NADIR’s SPIRA-CEL

® modules are readily available in different constructions depending on the area of application: Process industry, biotechnological processes and food industry.

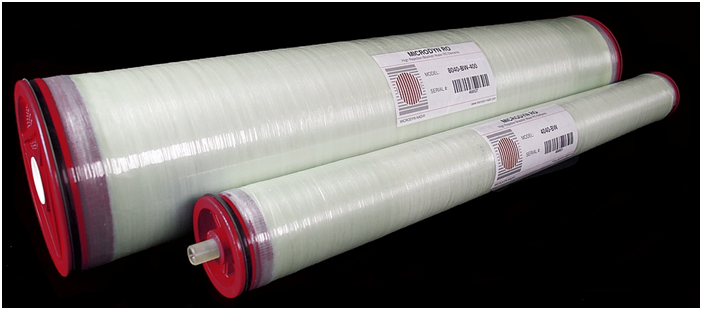

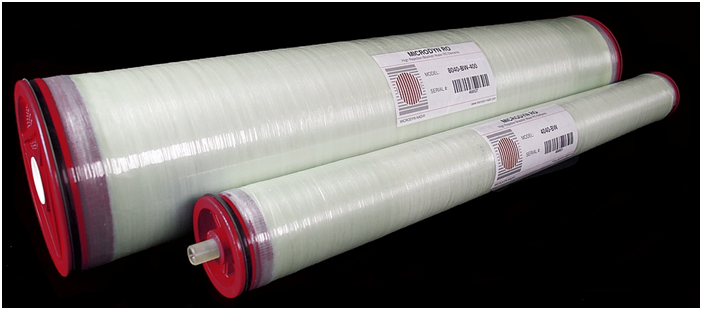

MICRODYN RO

High Rejection Brackish Water RO Elements

Reverse osmosis (RO) membranes remove a large majority of contaminants from water, including even the smallest monovalent ions. RO is capable of rejecting over 99% of dissolved salts (ions), particles, organics, and more from the feed water.

The MICRODYN RO series of brackish water RO membranes is ideal for water purification applications. These elements feature our best membrane for directly replacing competitive RO products and offer very high solute rejection. MICRODYN RO elements are available globally and can be sourced from our plants in the United States, China, and Germany.

Direct replacements to seamlessly meet your RO needs:

MICRODYN RO elements are available in standard 4” and 8” spiral-wound designs to meet all of your new equipment and direct replacement needs. With permeate tubes sized to match standard designs, MICRODYN RO elements make it easy to directly replace competitive RO elements. For detailed technical information, please see our technical data sheet.

· MICRODYN RO 8040-BW-400:

Technical Data Sheet

· MICRODYN RO 4040-BW

Technical Data Sheet

MICRODYN RO elements are ideal for a variety of applications:

· Boiler feedwater

· Industrial process water

· Water re-use

· Polishing effluent from MBR or UF

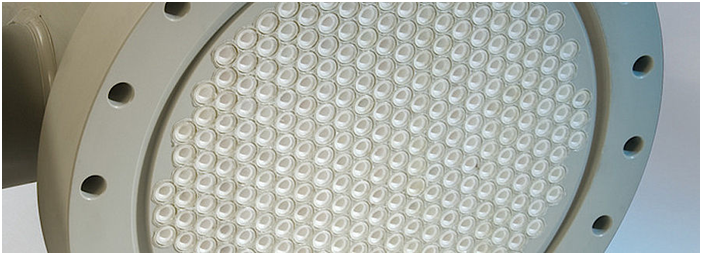

Hollow Fiber Membrane Modules for Water Filtration (Ultrafiltration)

The conventional treatment of water is based on a multi-step process including pre-filtration, precipitation/flocculation/coagulation, sedimentation, sand filtration and finally disinfection.

Despite this complex process technology a constant effluent quality at raw water deviations is not always possible. Therefore, the dosage of additives needs to be adjusted which could result in high operating costs.

Physical separation processes with membrane technology – ultrafiltration for water filtration

Physical separation processes using membrane technology, on the other hand, display another wastewater treatment option. Especially ultrafiltration is an established technology with respect to environmentally friendly and almost residue-free water treatment processes.

Double asymmetric hydrophilic low fouling/high flux hollow fiber membranes

The AQUADYN

® hollow fiber modules with their hydrophilic low fouling – high flux membranes are excellent solutions for the efficient treatment of large volumes of water. They are operated in dead end mode.

The double asymmetric hollow fiber membranes, which are integrated in our ultrafiltration modules for water filtration, offer another advantage over single asymmetric membranes. Bacteria, solids and turbidity can be rejected effectively due to a filtration layer (ultrafiltration membrane) inside and outside the hollow fiber. Therefore, problems such as pore clogging during

backflush do not occur.

Plant engineering – plant operation – applications for AQUADYN® modules

Plant Structure

-

compact design allows for smaller plant sizes

-

high level of automation possible

Plant Operation

-

easy pre-treatment even at high raw water turbidity

-

continuously high and stable permeate performance

-

modular construction provides high flexibility for fluctuations in water demand

-

high recovery rates

-

minimal cleaning demand resulting in:

-

less permeate consumption for cleaning

-

high operational availability

-

low operating costs

Applications for AQUADYN® ultrafiltration modules

-

effluent treatment after biological treatment plants

-

pre-treatment for reverse osmosis (sea water desalination and boiler feed production)

-

stormwater treatment

-

production of industrial water from river water

-

cooling water

-

filtration of industrial water for the food industry

-

borehole water treatment

-

karst water filtration

-

drinking water filtration

SEPRODYN® Tubular Modules

Tubular Modules for Fine Filtration

SEPRODYN® filters are crossflow microfiltration modules used to separate suspended solids larger than 1.0 micron. The highly porous membrane contributes to a very high product flux and, with the ability to employ periodic back flush, stable and efficient processes for water filtration and wastewater treatment are achievable.

Stable tubular membrane modules – usable across the full pH range 0 to 14

SEPRODYN® tubular modules use a smart processing technique that allows membranes to be used in applications which require highly stable polymer materials. These membrane modules can be used across the entire pH-range from 0 to14 and are especially recommended in applications that require a high resistance against abrasive substances.

SEPRODYN® tubular modules for the filtration of solutions with high solids content

SEPRODYN® membranes are self-supporting and extremely robust tubular membranes. Because of their large inner diameter of 5.5 mm, liquids with a high percentage of suspended solids can be filtered. The SEPRODYN® solution offers an extremely high packing density per module.

The tubular membranes are made of ultra-high molecular polyethylene made in a patented process by MICRODYN-NADIR. The membrane structure is symmetrical and even across the entire wall thickness. This ensures that the membrane separation performance is not affected when the membrane surface is damaged by abrasive material. The membranes are welded together with the housing. Since the housing and the membrane are both Polyethylene, a very stable bond between the membranes and the housing is achieved.

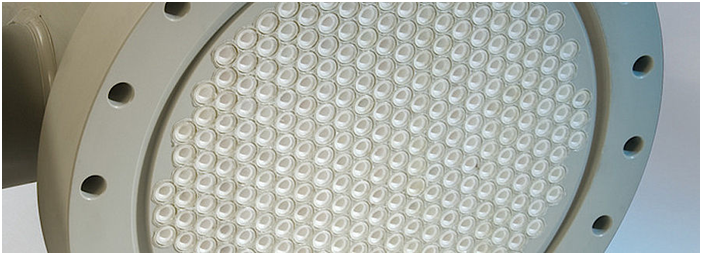

MICRODYN® MF Modules

Tubular and Capillary Modules for the Microfiltration

MICRODYN tubular and capillary filter modules have been developed for crossflow microfiltration. This type of crossflow microfiltration represents a modern filtration method for the separation of suspended particles or emulsified liquids.

MICRODYN – high integrity due to symmetrical membrane structure

The highly porous symmetrical structure of the MICRODYN membrane leads to extremely high permeability rates. The pore size distribution is very narrow making sharp separations possible. The MICRODYN membrane is very resistant to abrasion and other mechanical damage due to its homogeneous construction, unlike asymmetrically structured ceramic membranes. It also has great chemical resistance because of the material properties of polypropylene.

MICRODYN modules: hollow fiber modules, capillary modules and tubular modules

The MICRODYN membranes are available as hollow fibers, capillaries and tubes. Capillary and hollow fiber membranes are potted in the module housing. The centrifugal casting of the potting material guarantees high product quality. Tubular membranes are welded together integrally with the housing. This makes gaskets or other sealing materials unnecessary. The modules are therefore extremely chemically stable and robust (pH range 0 to14).

High and stable filtration performance with MICRODYN polypropylene membrane modules

Any surface deposits formed during filtration can be easily

minimized by:

· adjusting the velocity of the feed flow

· periodic back washing (PRS)

· chemical cleaning in reverse flow to the filtration flow

These mechanisms result in consistently high performance levels and many years of trouble-free operation. Polypropylene is resistant to many organic and inorganic chemicals, including most acids and caustics, with the exception of oxidants. The MICRODYN microfiltration modules can be used for the filtration of most liquids and mixtures of these chemicals.

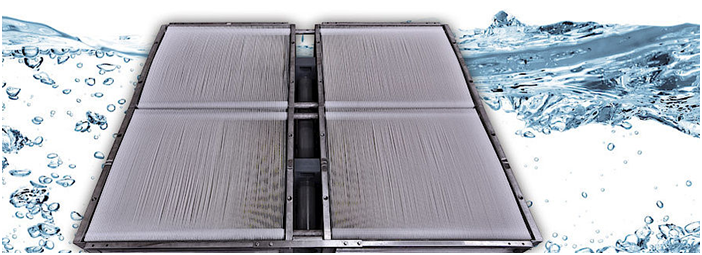

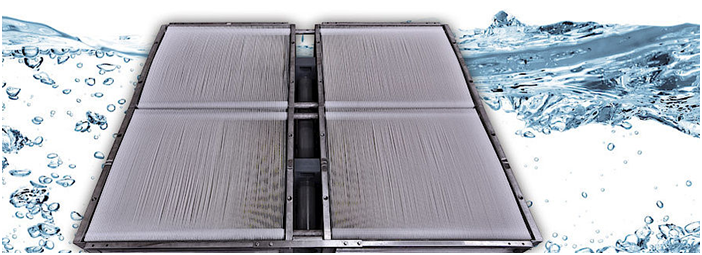

MICRODYN BIO-CEL® MBR

Submerged MBR-Module based on Flat Sheet Membranes (Membrane Bioreactors)

Tighter discharge regulations, urbanization and the increase in water recycling have made

Membrane Bioreactors (MBR) the leading innovation in

wastewater treatment through conventional activated sludge.

Traditionally, activated sludge treatment relies upon solids settling in a secondary clarifier to separate the biomass from the treated wastewater. This process has the disadvantages of running at a lower MLSS (Mixed Liquor Suspended Solids), thus requiring more space and producing lower and varying quality effluent.

Operation with high solids content (MLSS) and constant flux rates

With Membrane Bioreactor (MBR) technology, the clarifier is replaced by a physical barrier – the BIO-CEL

® membrane module. This physical barrier enables the Membrane Bioreactor (MBR) to operate at higher MLSS levels, thereby requiring a

smaller overall footprint. The BIO-CEL

® membrane modules operate within the ultrafiltration spectrum, producing high capacities of quality effluent at consistent flows.

Efficiency, reliability and cost effectiveness as well as longterm viability are just some of the characteristics of the BIO-CEL

® module. The effluent is suitable for:

-

recycling applications

-

irrigation purposes

-

use as feeds for process water

-

BIO-CEL® offers the best of the two predominant module configurations on the market

BIO-CEL

® combines the benefits of traditional hollow fiber and plate and frame configurations without any of their inherent disadvantages.

The self-supporting membrane sheet is just 2 mm thick, resulting in an extremely high packing density and very low specific energy consumption.

Moreover, the laminate offers a

self-healing mechanism. In case of damage caused to the membrane the spacer material in between the BIO-CEL

® membrane laminate sheets allows for a sealing of the damage through the help of the biomass in the system. Even after the occurence of a severe detraction of the membrane laminate, solids and bacteria can still be rejected by the membrane bioreactor module.

The smart design of the BIO-CEL® membrane bioreactor (MBR) module

The BIO-CEL

® configuration is based on flat sheet technology, with crossflow inhibiting clogging and reducing downtime.

The modules´ open top and bottom channels reliably prevent the deposition of sludge and fiber accumulation during the continuous crossflow operating process. The self-supporting structure of the membrane module enables

frame-free installation, thus eliminating blockages around the external boundaries of each component. The membrane module is configured to allow for consistent permeate flow and a highly effective

backflush over the entire membrane surface. In summary, the BIO-CEL

® offers

high packing density with optimal separation.

For large-scale applications with a total inflow to the MBR plant of > 2,000 m

3/d of wastewater to be treated the BIO-CEL

® XL with a total membrane area of 1,920 m

2 has been developed.

For further information on MICRODYN-NADIR products, please do not hesitate to contact our technical service team. We look forward to helping you meet all of your membrane needs.

Contact:

Tel:+86 592 6514970

Email:market@guochukeji.com

Skype:18060902001

WhatsApp:18060902001

WeChat:18060902001

TM: guochukeji

QQ:1641011431