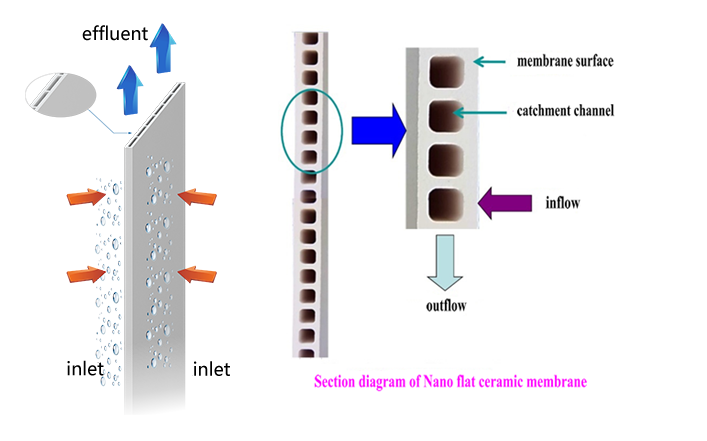

Flat ceramic membrane is an asymmetric membrane formed by the preparation of inorganic ceramic membrane materials. The tube wall of flat ceramic membrane is covered with micro pores. Under pressure, the feed liquid flows through the membrane tube or the outer surface of the membrane, and the small molecule (or liquid) goes through the membrane, the macromolecular substance (or solid) will be trapped by the membrane. Thus, it achieves separation, concentration, purification and environmental protection.

How it works

Characteristic

High Reliability and Long Operational Life

Having superior mechanical, thermal and chemical durability, our robust design membrane can be in service for 5 times longer than an organic one. To some extend, it also reduces the cost.

Small Footprint

High flux enables the ceramic membrane to save more than 50% of the surface area of the membrane compared with the organic material.

Easy to Maintain and Environmental Friendly

Less fouling potential and less repairs.

Stable Performance

High strength membrane surface and high corrosion resistance, so it is very suitable for separation of hard substances in water and solvent containing wastewater treatment.

Cost Effective Separations

The superior characteristics of flat ceramic membrane provide economical solutions for high added value macro-molecule concentration, effluent recycling or reduction and difficult fluid clarification.

Various Applications

The advanced design enables an unprecedented technical and economical treatment in different fields of applications.

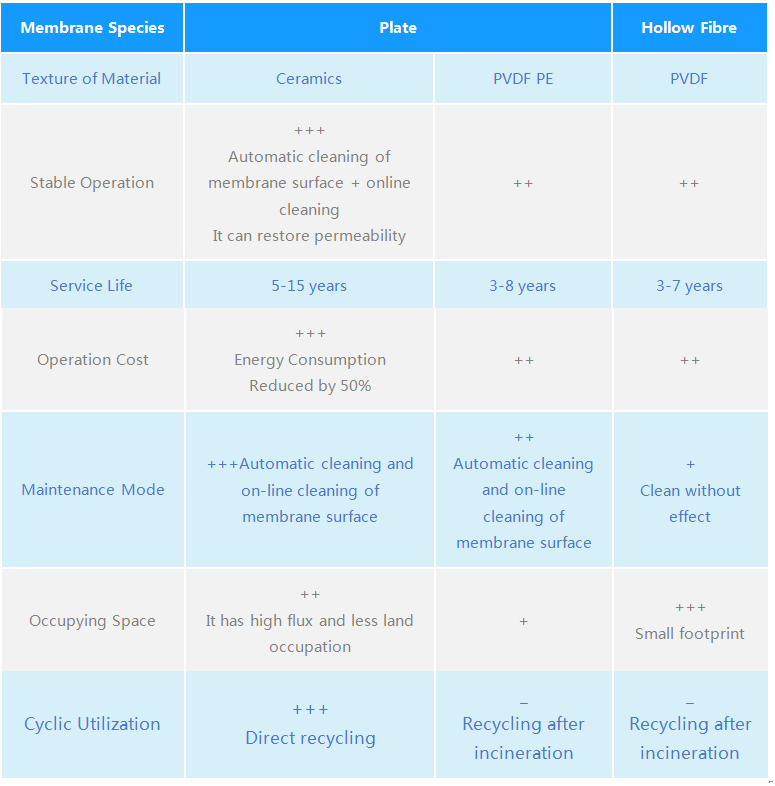

Comparison of Flat Ceramic Membrane

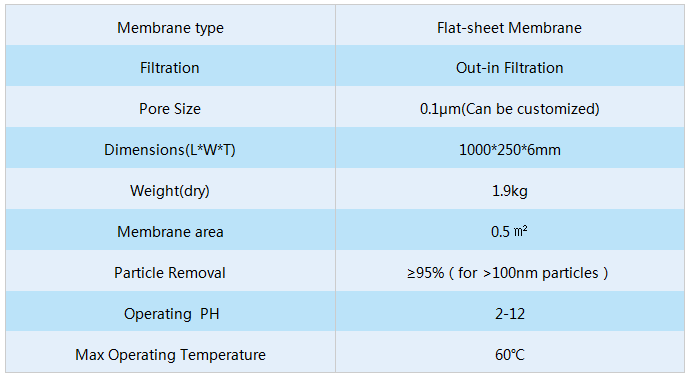

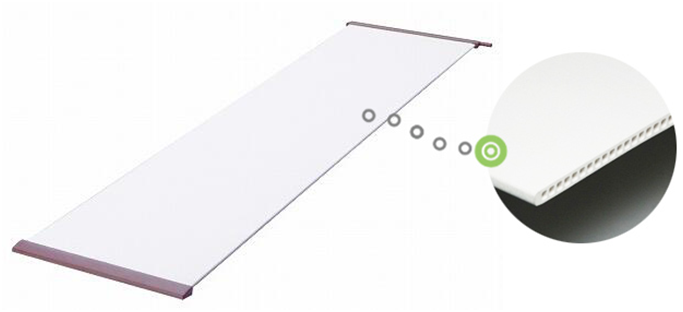

Specification of membrane

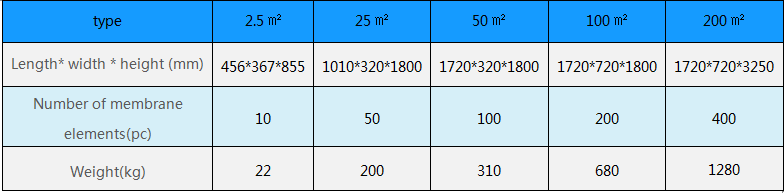

Specification of Modules

Characteristic

Concrete Application

Characteristic

Concrete application

Municipal sewage; aquaculture wastewater; waste leachate

Characteristic

Ceramic membranes are widely used in various industrial water treatment applications. For example, front end pre-treatment as reverse osmosis or nanofiltration. The new generation of ceramic membrane requires limited maintenance,and the operation life is longger. Besides, it can operate in different environments, such as corrosive agents, solvents, polymers, oxidants and the presence of strong acids

Durability is also manifested in higher backflushing frequencies and the ability to withstand periodic high load sludge up to 50.000pp of the work environment. Because of high-pressure cleaning and backflushing, ceramic membrane has a higher flux recovery rate. Compared with other membranes with the same precision, ceramic membrane has a very high flux.

Specific applications (major application areas)

Contact:

Tel:+86 592 6514970

Email:market@guochukeji.com

Skype:18060902001

WhatsApp:18060902001

WeChat:18060902001

TM: guochukeji

QQ:1641011431