Diffusion dialysis equipment principle

Diffusion dialysis equipment is a use of semi-permeable membrane or select the ion exchange membrane through the ion exchange solution from the high concentration side of the membrane through the membrane to the low concentration side of the technical equipment. This technique is based on the concentration difference as a driving force, so also known as concentration dialysis or natural dialysis. It is mainly used for the separation and purification of organic and inorganic electrolytes. In the environmental engineering is mainly used for acid and alkali waste treatment and recovery.

Diffuse dialysis equipment to recover waste acid

The diffusion dialysis apparatus is a series of structural units composed of a certain number of membranes; each of which is separated by an anionic homogeneous membrane into a dialysis chamber and a diffusion chamber, which is operated by countercurrent operation on both sides of the anionic homogeneous membrane When the waste acid and the receiving liquid (tap water) are added, the concentration of acid and its salt on the waste acid side is much higher than that on the side of the water. According to the diffusion dialysis principle, the waste acid and its salts are present due to the concentration gradient Diffusion chamber penetration trend, but the membrane has a selective permeability of the anion, so under the effect of poor concentration, the waste acid side of the anion is attracted and smoothly through the membrane channel into the water side. At the same time, according to the neutral requirements, will also entrain the cation, because the H + hydration radius is relatively small, less charge; and metal salt hydration radius is larger, more charge, so H + will pass through the membrane, so waste the acid will be separated.

Application areas: steel, chemical foil, battery, titanium dioxide, wet copper, aluminum, polysilicon, electroplating, titanium processing, wood saccharification, rare earth and other non-ferrous metal smelting and other industrial fields. The recovery rate of acid on the device can reach more than 80%, metal ion removal rate of 90% or more.

Application of Diffusion Dialysis Equipment

1. Application of membrane diffusion dialysis equipment in chemical foil industry

Chemical foil corrosion process, resulting in a lot of waste acid. These waste acid emissions (even with lime and neutral), not only cause waste of resources, so that product costs increase, but also lead to serious environmental pollution, affecting and restricting the survival and development of enterprises. To a medium-sized low-voltage electrode foil production enterprises, for example, daily emissions of 15 to 20% of 30 tons of waste hydrochloric acid, equivalent to waste 15 to 20 tons of 31% of the finished acid. The use of diffusion dialysis technology, which can effectively recover the hydrochloric acid, hydrochloric acid to save the economic benefits of more than 200,000 yuan, but also to solve the problem of environmental pollution, economic and social benefits is very impressive.

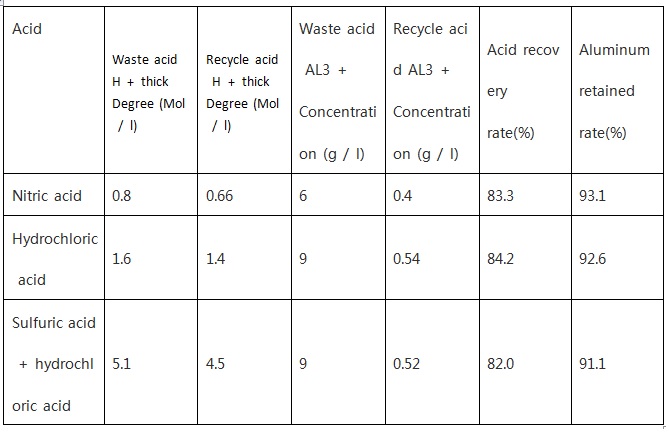

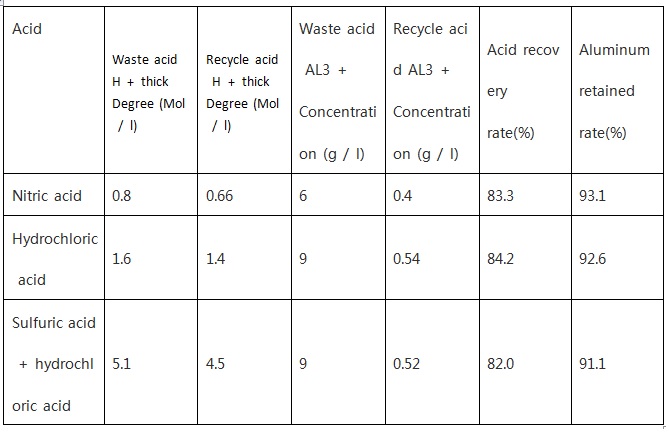

2. Application of film diffusion dialysis equipment in aluminum industry

Aluminum anodic oxidation process, resulting in a lot of waste acid. These waste acid if the neutral treatment is not only the full use of acid, and consume a lot of alkali. General aluminum anodic oxidation of the waste acid concentration of 18%, metal ion concentration of 1.5%, with a diffusion dialysis treatment of the acid solution, which can recover more than 85% of the acid composition, and the retention of aluminum ions can also be achieved 90%. Recovery acid solution acid concentration is stable, the subsequent acid with easy, and homogeneous material on the production of small impact.

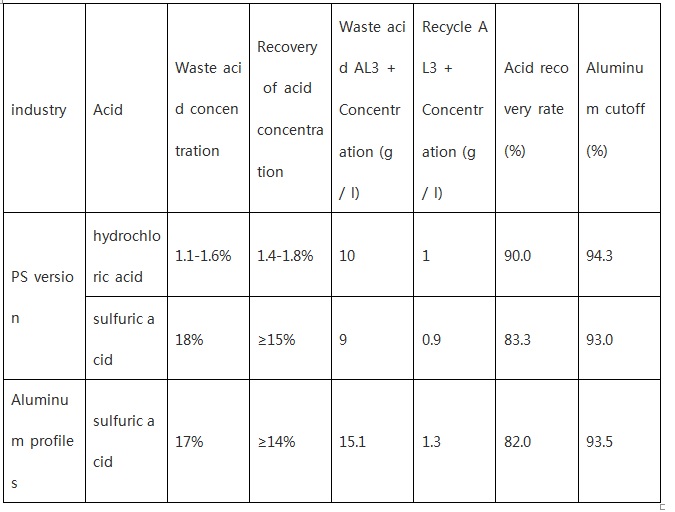

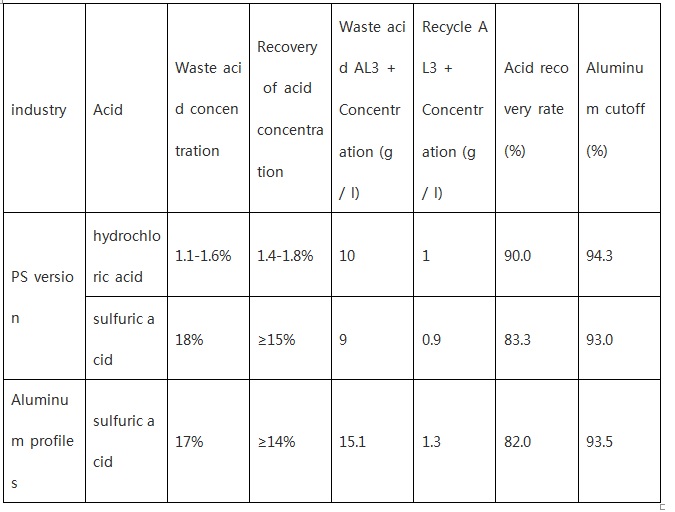

3. Application of film diffusion dialysis equipment in PS version industry

In the production of printing PS version of the process, resulting in a large number of hydrochloric acid liquid, sulfuric acid and other waste liquid emissions. Not only cause waste of resources, so that product costs increase, but also lead to serious environmental pollution, affecting and restricting the survival and development of enterprises. The use of diffusion dialysis technology for the treatment of waste liquid, not only the majority of aluminum ions to remove the waste liquid recycling cycle, while stabilizing the production of dielectric and oxidation solution fluctuations, to promote the production of PS version of the quality improvement.

4. Application of Membrane Diffusion Dialysis Equipment in Graphite Industry

High-purity graphite industry Chemical pickling method to improve the graphite process will have a lot of waste acid production, waste acid and emissions need to consume a lot of alkali, while generating a lot of residue, improve production costs and environmental pollution, such Waste acid after diffusion dialysis treatment, 80% of the acid recycling cycle for enterprises to reduce production costs, while reducing emissions of waste for enterprises to create more social benefits.

5.Application of Membrane Diffusion Dialysis Equipment in Electroplating Industry

Electroplating industry in the production of copper, tin, galvanized, nickel plating process before the need for acid surface treatment, resulting in a large number of waste acid, such waste acid composition is complex, high acid concentration, and emissions are a lot of waste of the alkali and produce a lot of residue. After 80% of the acid is recycled and recycled, 90% of the metal ions are retained for subsequent heavy metal treatment, saving the acid while reducing the use of alkali and reducing the generation of solid waste residue for the enterprise Cost savings while creating more economic and social benefits.

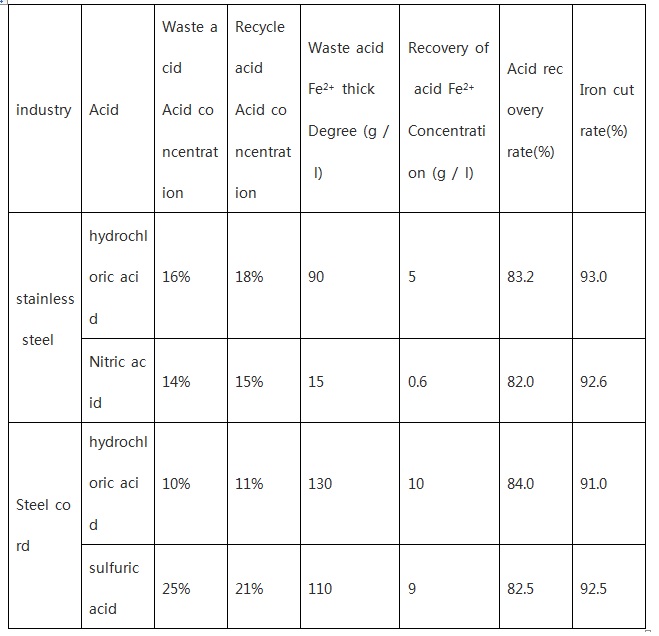

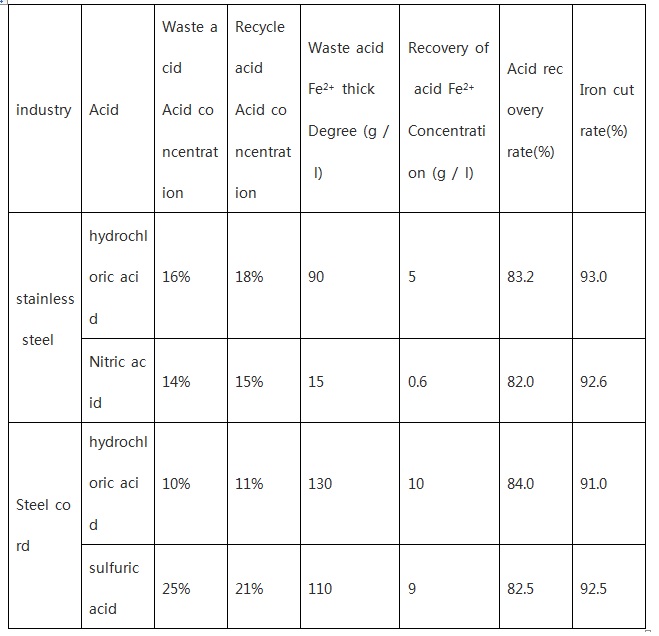

6. Application of Membrane Diffusion Dialysis Equipment in Iron and Steel Industry

Stainless steel, steel cord and other iron and steel industry in the acid solution with sulfuric acid, hydrochloric acid and nitric acid - hydrofluoric acid lotion. China's waste discharge such as amazing, the current treatment of such waste is also mainly used acid and alkali, cooling crystallization and other methods, but compared with the membrane dialysis method, there are various methods of waste of raw materials and high costs. Membrane treatment of such waste, available acid water (generally iron <0.5%) as the absorption of liquid to recover the acid in the acid, recycling acid to return to the system to continue to use, so that both enterprises save the resources, but also solve the Environmental pollution problems.

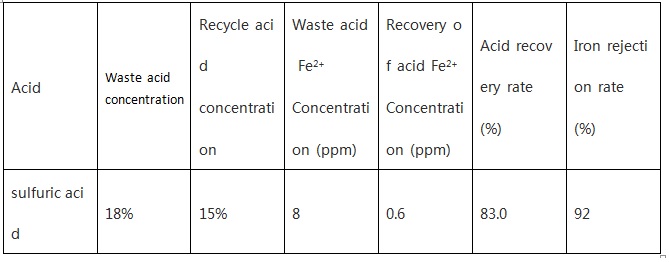

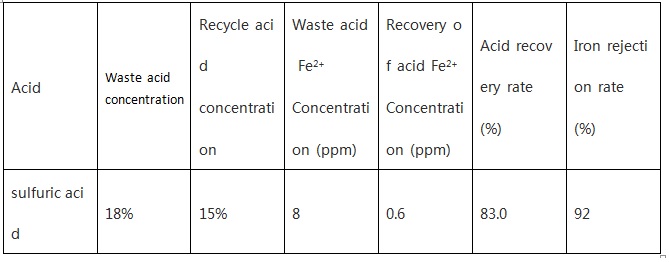

7.Application of Membrane Diffusion Dilution Technology in Battery Industry

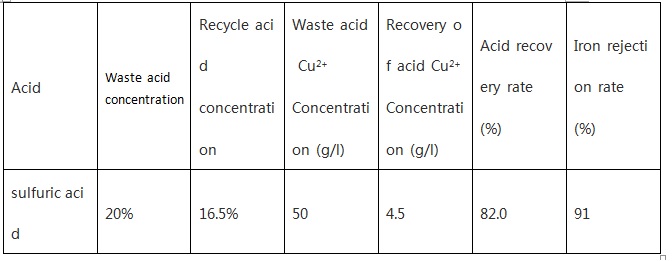

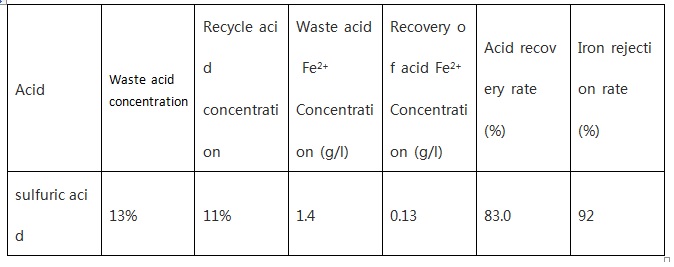

After the plate into the waste acid due to pickling the plate after the waste iron in the iron content increased. If the re-use of iron ions due to the existence of negative electrode with the formation of corrosion micro-battery, causing negative metal dissolution; electrolyte waste acid high iron content caused by self-discharge of the battery to reduce battery capacity and reduce battery life. With the diffusion dialysis method to recover the waste oil and waste acid, the iron ion retention rate is above 90%.

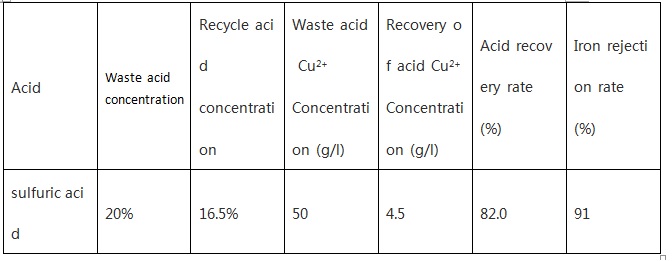

8.Application of Membrane Diffusion Dilution Technology in Hydrometallurgical Industry

Wet copper production in the production of a large number of electrolytic solution, if lime and, in addition to the loss of acid and copper, but also lead to environmental problems. With the membrane diffusion dialysis recovery of electrolytic solution in the waste acid and then return to the system, so that both for the enterprise to save resources, but also to solve the problem of environmental pollution. The process is as follows:

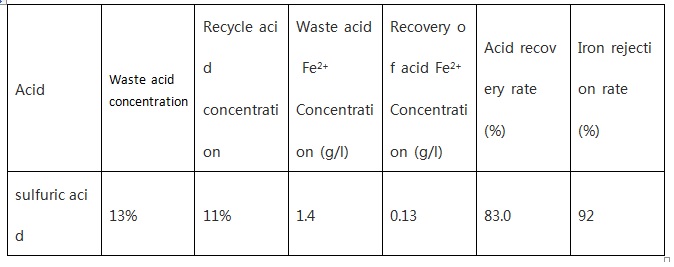

9. Application of Membrane Diffusion Dilution Technology in Polysilicon Production Industry

Polysilicon is the main raw material for the manufacture of monocrystalline silicon, solar cells and high purity silicon products. In the production of polysilicon will produce a lot of waste acid. With the diffusion dialysis method to recover the waste acid and then return to the system, so that both for the enterprise to save resources, but also solve the problem of environmental pollution.

Contact:

Tel:+86 592 6514970

Email:market@guochukeji.com

Skype:18060902001

WhatsApp:18060902001

WeChat:18060902001

TM: guochukeji

QQ:1641011431