The membrane bioreactor combines membrane separation technology and biological treatment of water purification technology, the world running MBR systems are reflected in the following advantages:

(1) The solid-liquid separation rate is high, and the effluent quality is good. City life sewage treated by MRR, COD, BOD and turbidity are very low, almost does not contain SS, most bacteria and virus interception, generally do not need the three stages of treatment, water quality has reached or exceeded the Ministry of construction "miscellaneous domestic water quality standard", can be directly used as city landscaping, sanitation, fire and water.

(2) The interception function is effective. The MBR system can make the microorganism completely entrapped in the bioreactor, the reactor hydraulic retention time (HRT) and SRT (SRT) completely separated, which makes the system in the HRT is short and SRT long running condition possible. This can prolong the residence time of wastewater refractory organic matter degradation in large part in the reactor, enhanced biological treatment, the nitrification system SRT long, the growth and reproduction of the long generation time of nitrification song favorable, so the system has better removal efficiency of nitrogen and phosphorus, while reducing the moment of HRT can reduce the sludge load (F/M), to reduce the amount of excess sludge, sludge reduction in addition, due to the complete separation of HRT and SRT, easy to control, realize the optimization process.

(3) Withstand shock resistance load. Due to high concentration of microorganisms (2g/L or higher) in the device with high volume load (can reach 4-5kgC0Dcr/m3 - d), under the conditions for large fluctuation, the removal effect of the system changed little, water quality has been treated is stable.

(4) The system has the advantages of simple structure, compact equipment, and small footprint; it is also easy to operate.

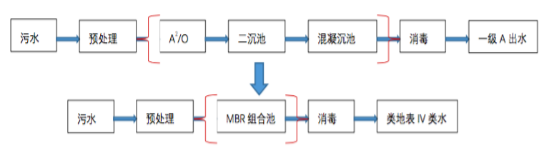

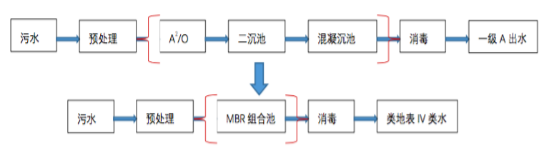

In order to overcome the problems of activated sludge process, MBR process and activated sludge process are combined, in reference to the CASS (cyclic activated sludge system) technology, membrane bioreactor and denitrifying phosphorus removal process based on the idea, put forward two-level, three-level city sewage treatment with the steps envisaged.

(1) Anaerobic pool

The main function of anaerobic pool acts as biological selector, to ensure the optimum phosphorus release condition of polyphosphate bacteria, to quickly absorb and remove some easily degradable dissolved organics by rapid transfer of enzymes, and thus to produce the process of matrix accumulation and regeneration, which is helpful to select flocculation bacteria and prevent sludge bulking. At the same time, a large number of sewage flow can also play a role in buffering and regulating water quality, compared with the traditional activated sludge process, the new process has increased on-line separation, off-line precipitation chemical phosphorus removal unit. It is well known that the use of biological phosphorus removal technology is mainly sufficient to reduce the amount of chemical agents. However, in the following two cases the biological phosphorus removal effect is not good:

1. To meet the nitrification and prolong the sludge age.

2. The ratio of C0D/P in water is too low, in order to solve this problem, this optimization scheme by increasing the phosphorus separation unit, to avoid the adverse conditions of biological phosphorus removal, while providing the possibility of phosphorus reuse. On-line separation of supernatant (generally 30~40mg/l) of anaerobic end (the supernatant liquid is adjusted according to the water quality and sludge age at any time, the recommended value is 10%), and the iron or magnesium salts are added to the sedimentation unit in an off-line manner, after treatment, the sludge is no longer returned to the sewage treatment structure, so the effect of chemical phosphorus removal on the sludge activity is eliminated. The optimization scheme of biological phosphorus removal supplemented by chemical removal, mainly using PAOS (polyphosphate)/DPB to phosphate has a high affinity characteristic, very easy to obtain very low effluent concentration of phosphorus, and in the premise of ensuring good effluent quality, greatly reducing the amount of COD, it provides possibility to improve the phosphorus.

(2) Hypoxia/aerobic pool

Hypoxia/aerobic pool is set up for three purposes: one is the formation of hypoxic environment for simultaneous nitrification and de-nitrification system, further improve the effect of nitrogen and phosphorus removal. The second point is to ensure the full regeneration of sludge (aerobic pool) does not affect the effective removal of nitrate. Because the sludge regeneration degree was controlled, so the lowest water content between DHB and glycogen in low load sludge (phosphorus bacteria) is guaranteed, which means it can guarantee good removal rate of phosphate. The third point is because of the higher oxygen concentration of sludge from the main reaction zone (up to 6mg/L), for the same flow to the anoxic reaction of the sewage concentration is too high, so it can first return to hypoxia/aerobic pool, from here into the anoxic zone.

(3) Anoxic zone

The function of anoxic zone is: wastewater goes into the anoxic zone through the anaerobic pool, the denitrifying bacterium in the same flow sludge uses the Influent organic matter as C source to restore the large amount of nitrate nitrogen (N0

3 -N) in the reflux mixture to N

2, thus achieves the goal of de-nitrification. At the same time, the optimized anoxic zone also has some advantages: first of all, reduce the nitrate concentration of the same flow to the anaerobic zone by de-nitrification. Second is denitrifying phosphorus removal, a large amount of nitrate-enriched mixed liquor reflux from the main reaction region provides a good electron acceptor for denitrifying polyphosphate, it uses nitrate oxidation to synthesize large amount of PHB and release phosphorus in anoxic region, which provides the conditions for further removal of nitrogen and phosphorus in the anoxic/aerobic environment of the main reaction zone.

(4) Main reaction zone

The integrated membrane biological reaction is used in the main reaction zone. Membrane components immersed in the aerobic zone, the main problem for using membrane is membrane fouling. According to the cause of membrane fouling, the effective measures can be taken to prevent membrane fouling, which is mainly embodied in the following aspects:

1. The membrane assembly adopts microfiltration hollow fiber membrane with cell immobilization technique. Because the hollow fiber membrane has biodegradation function, it also has separation function. The bio-membrane grows on the infiltrated fiber carriers, the air is penetrated and flow to bio-membrane layer through the carrier, the microorganism in the bio-membrane stratified automatically, can prevent secretion of extracellular polymers blockage caused by direct contact of denitrifying bacteria and membrane surface.

2. The inlet mode is a wrong flow type. The aeration device is arranged at the lower end of the film, and the flow effect of the membrane surface is realized by using the micro-pore aeration and the upward shearing force of the aeration liquid. In order to reduce the concentration of polarization and scaling problems, water takes away the trapped solute in time. It reduces membrane clogging.

3. Sewage pushing flow into the main reaction area from the lower end of the partition between the anoxic zone and the main reaction zone, use of the aeration of the lower end of the anoxic environment to further de-nitrification. In order to improve the dehydrogenation of phosphorus removal effect, it can also reduce the likelihood of denitrifying bacteria and membrane surface contact. At the same time, in order to adapt large water treatment of the sewage treatment plant, multiple sets of membrane components can be used in parallel settings, each group of membrane components can be alternately converted, the film will not be permanent loaded, it is easier to control membrane pollution, the use of multiple sets of membrane components in parallel with another advantage is that some of the membrane components can be taken out and put into the maintenance and repair, can significantly improve the performance of the device.

(5) System configuration

Pressure gauge, liquid level meter and flow meter are equipped in aerobic zone. In the anaerobic and anoxic / aerobic pool and anoxic zone is also equipped with the redox potential of online monitoring, the function of each configuration unit is:

1. Pressure gauge: used to monitor the membrane filtration pressure changes.

2. Liquid level meter: used to control the liquid surface of aerobic zone.

3. Water flow meter: used to control the flow of membrane effluent.

4. Redox potential of online monitoring: through the measurement of the redox potential in each area to control the same flow to solve the problem of multi-channel reflux pipeline. The whole system is operated by programmable logic Controller (PLC) automatically, which makes the operation process simpler.

(6) Potential advantages of the new process

1. Compared with the existing urban sewage treatment process, under the premise of ensuring good water quality, three levels of treatment are eliminated, and investment is saved.

2. Compared with the traditional activated sludge process, primary sedimentation pool,two sedimentation pool, sludge thickening pool and sludge digestion pool are eliminated, saving the processing area of the plant, raw water can go directly into the reaction zone through two grilles.

3. Compared with the CASS process, in addition to the elimination of three levels processing, also eliminates the decanting device, improve the water quality (because in actual engineering practice, the decanter is difficult to meet the design requirements, have more effluent suspended solids, the concentration is higher, it is difficult to ensure the water quality), it also improves the utilization ratio of the volume and saves energy.

4. Compared with the existing MBR process technology, the operation is stable and reliable, convenient operation management, it is easy for membrane cleaning and replacement, and it saves labor cost and area. In addition, reducing the degree of membrane fouling can maintain higher membrane flux in longer operation cycle.

5. The effluent quality is good, can be directly used for non drinking water, water with the Nano-filtration (NF) or reverse osmosis device can produce high-quality drinking water and used to the underground.

6. The amount of surplus sludge is less, which reduces the two stage of pollution and the cost of sludge treatment.

7. T he whole device has the advantages of simple structure, compact equipment, small footprint, full on-line monitoring, convenient operation and management, and easy to realize automation.

8. With the development of MBR technology and the further improvement of reclaimed water reuse standard, the system is easy to optimize and upgrade.

Contact:

Tel:+86 592 6514970

Email:market@guochukeji.com

Skype:18060902001

WhatsApp:18060902001

WeChat:18060902001

TM: guochukeji

QQ:1641011431