Polisher ST is the next generation in single-use technology, designed as a cost-efficient option to increase biomass production in therapeutic recombinant protein processing. It is designed for use in most operating conditions for replacing the downstream Anion Exchange (AEX) polishing column in fed batch and/or continuous manufacturing processes. 3M Polisher ST is offered in a range of products suitable for early screening and process development of monoclonal antibody (mAb) processes and larger single use capsules for deployment in manufacturing processes in most polishing process conditions.

Polisher ST is a compact, small footprint solution. It has greater capacity for delivering higher purity and yield in the downstream polishing unit operation. This is a solution for a connected continuous downstream operation for the flexible facility of the future.

3M Polisher ST allows a facility strategy that can overcome scale limitations and enable cost-efficient manufacturing to support the growing demand for biologics.

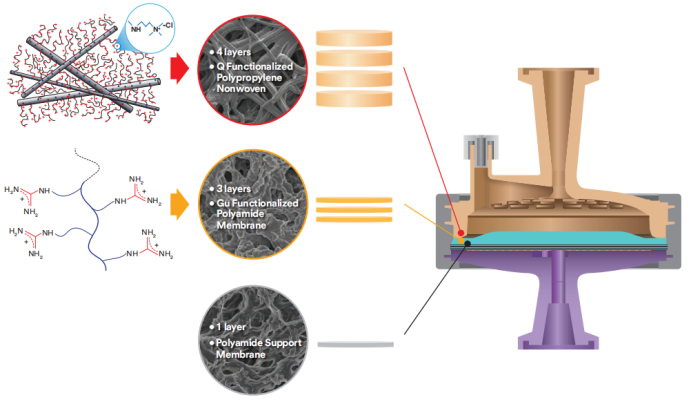

Polisher ST Innovative Design

Polisher ST Innovative Design

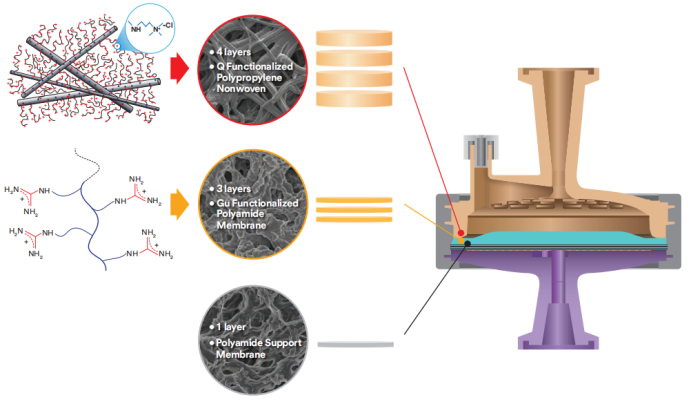

The composite purification media comprises three primary components: Q-functional FNW, guanidinium-functional AEX membrane, and support membrane. The Q-functional portion of the AEX media is composed of four layers of polypropylene nonwoven that have been surface functionalized with a covalently attached quaternary ammonium functional polymer.

The guanidinium-functional portion of the AEX media is composed of three layers of a polyamide microporous membrane, having a 0.8μm nominal pore size, that have been functionalized with a covalently attached guanidinium-functional polymer. The AEX media are followed by a single layer of a nominally 0.8μm pore size polyamide membrane support.

AEX performance of the guanidinium-functional membrane of Polisher ST provides HCP and virus reduction in a salt tolerant (ST) manner compared with conventional Q-functional AEX resins and single-use media, which rely solely on electrostatic interactions that can be screened at elevated ionic strength.

Guanidinium-functionalized membranes are used for high productivity chromatographic purification processes that match upstream efficiency without the need for oversizing.

Polisher ST single-use membrane adsorber purification solution is designed for the downstream processing of monoclonal antibodies (mAbs) and other recombinant proteins in flow-through mode. Polisher ST is designed to improve mAb development and manufacturing processes in most polishing process conditions.

Biopharmaceutical Purification Process Improvements:

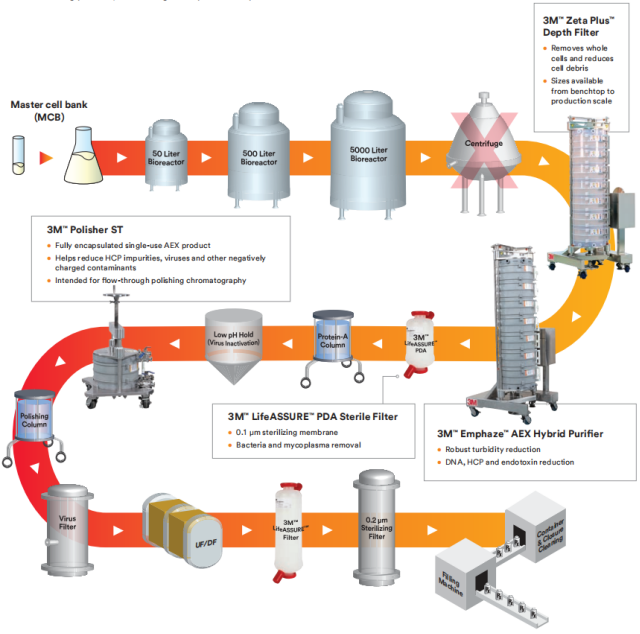

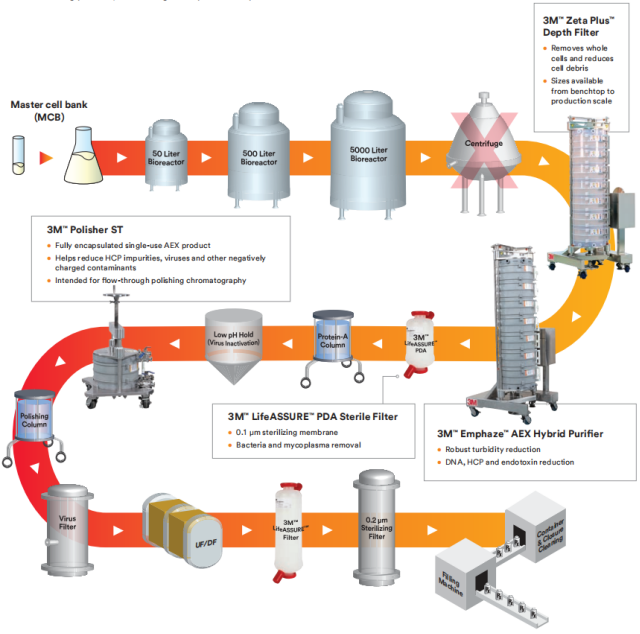

This process train illustrates the potential of combining 3M products to work together to create an intensified manufacturing process, eliminating other unnecessary process steps.

Polisher ST Performance:

Polisher ST Performance:

Polisher ST is designed for replacement of the Q-functional bead-based chromatography column with high throughput, cleaner effluent and lower total cost of ownership.

The nonwoven and membrane skeletons provide mechanical strength and durability, while the grafted hydrogel functionality creates a large three-dimensional surface area that contains a high density of functional groups with interconnected pores allowing for convective flow channels to achieve high flow rates during purification.

The high density of binding sites, together with a macroporous structure, enables high binding capacity for not only HCPs, but also large molecules, such as viruses and DNA. The high density of binding sites and low residence time results in high mAb recovery (>95%).

The high ligand density on the advanced anion exchange membrane of Polisher ST provides robust impurity removal, viral clearance, and a 50 to 100X higher mAb loading capacity than chromatography resin beads to further reduce media volume requirement. The impurity clearance performance (HCP ≤1000 ppm, ≤100 ppb DNA, and viral clearance) is independent of the load which could be as high as 10 kg/m², enabling downsizing of the unit operation.

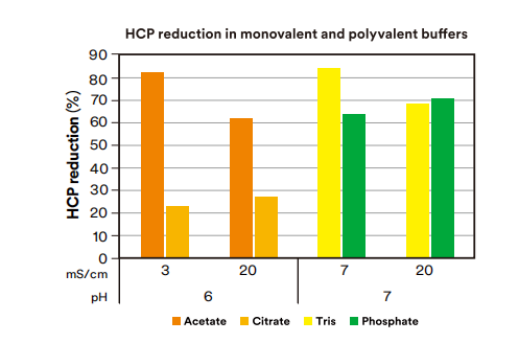

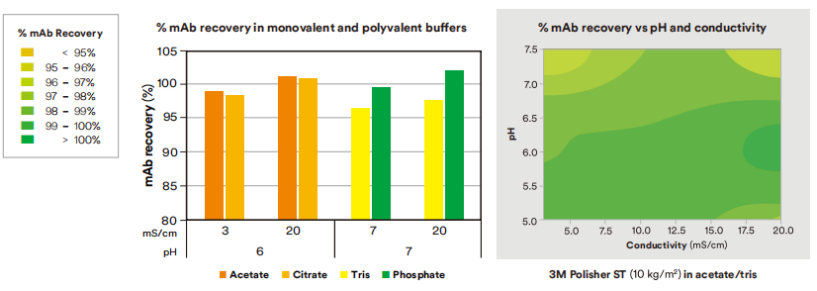

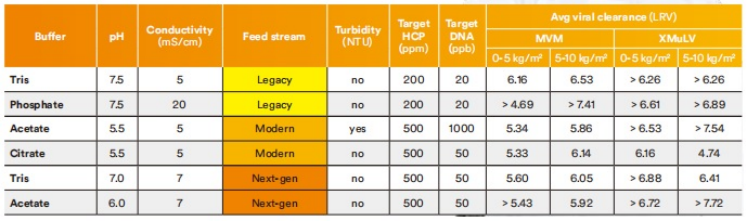

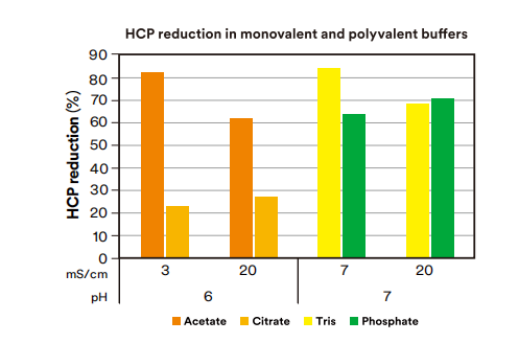

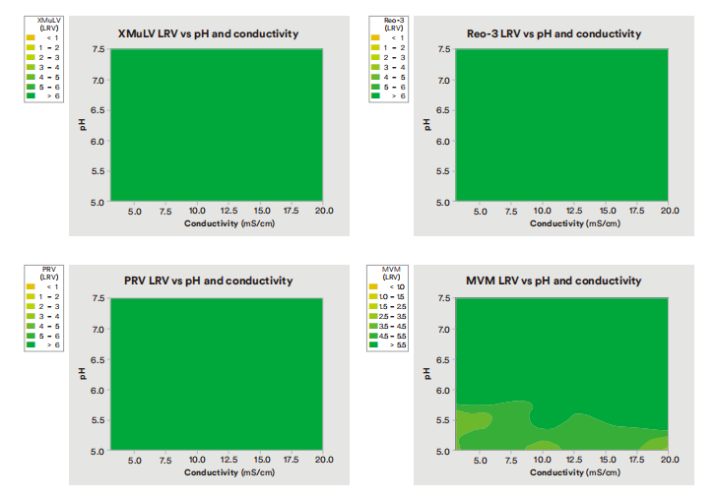

Polisher ST offers a combination of high dynamic antibody-loading (10 kg/m²) capacities with low residence time (about 0.2 min compared to 1 minute for traditional Q resin), opening the way to an intensified high-productivity, truly single-use purification platform. Robust viral clearance is achieved over a range of buffer and pH conditions, which provide a wide design space for operation, as shown in the data below. Performance is maintained at high conductivity (20 mS/cm) even in citrate buffer, which reduces the need for feed dilution or buffer exchange requirement resulting in a simplified process with reduced cost factors. AEX chromatography removes HCP and DNA and is also an effective virus removal step as part of an orthogonal viral clearance technology platform. Under process conditions of pH 5.5 to 7.5 and 5 to 20 mS/cm, 4 to 7 LRV can be achieved using 3M Polisher ST.

Polisher ST Test Data

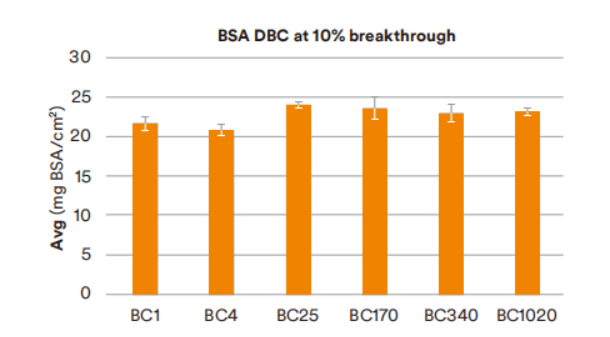

Dynamic binding capacity

Polisher ST Test Data

Dynamic binding capacity

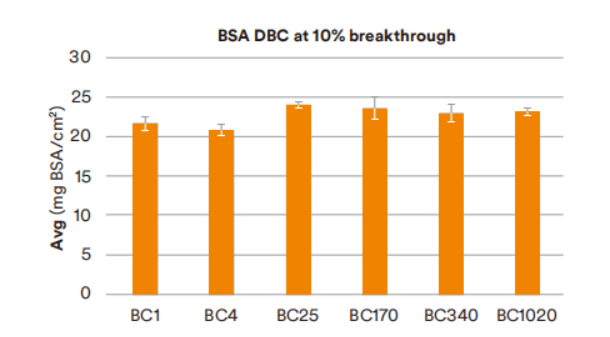

Polisher ST lab and scale-up capsules have target mAb loading capacities from 1g to 1kg. Larger capsules with target mAb loadings of 2.25kg and 16kg are planned. Scalability of capsules with different frontal media surface area was assessed by measurement of bovine serum albumin (BSA) protein dynamic binding capacity (DBC) as a simulant for HCP. The BSA DBC per unit area is quite constant across all capsules, having a mean value of 22.6g/cm² and a standard deviation of 1.4g/cm².

HCP reduction

HCP reduction

~500 ppm HCP in a VIN mAb pool

> 60% removal in Phosphate buffer,

> 22% removal in Citrate buffer

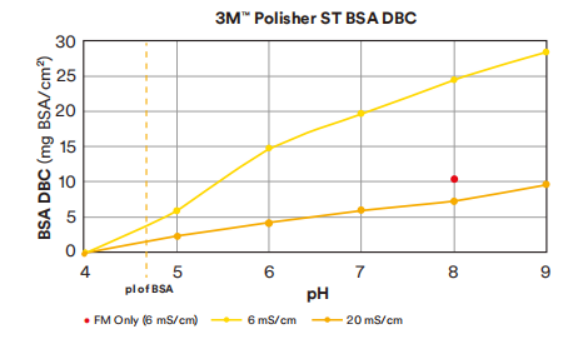

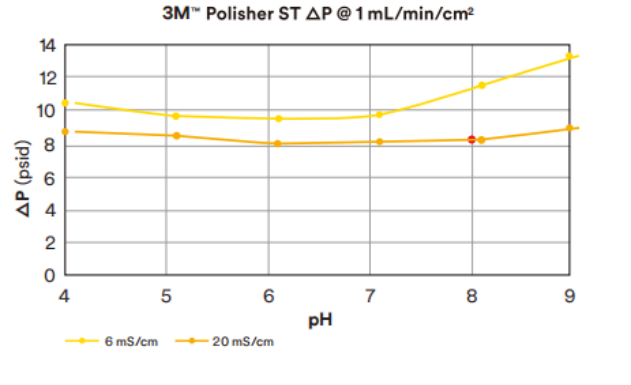

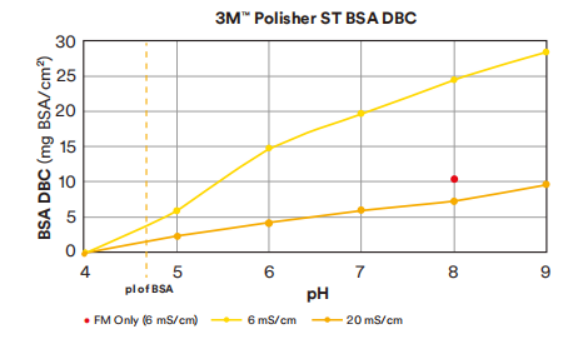

Consistent DBC under a wide range of pH and conductivity

Consistent DBC under a wide range of pH and conductivity

The BSA DBC specification for the functional membrane only is 7.8-12mg BSA/cm² in 25 mM Tris, pH 8, 50mM NaCl. High salt (20 mS/cm) reduces the capacity of the membrane by 2-3 mg/cm². Additional capacity provided by the FNW at conductivities < ~10 mS/cm.

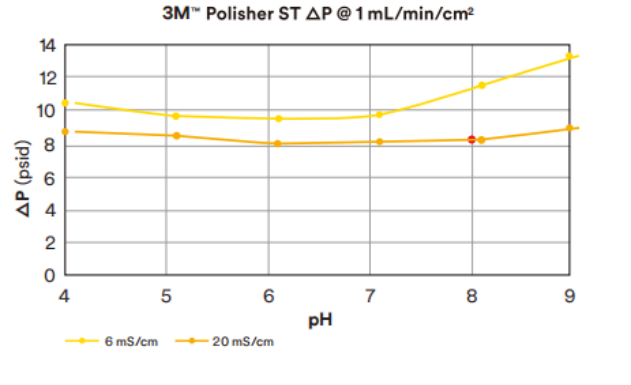

The differential pressure (△P) specification for the functional membrane only is < 10 psid in 25 mM Tris, pH 8, 50mM NaCl at 1 mL/min/cm². Lower salt (< 6 mS/cm) slightly increases pressure due to contribution from FNW. Maximum differential pressure (all capsule sizes) is 35 psid.

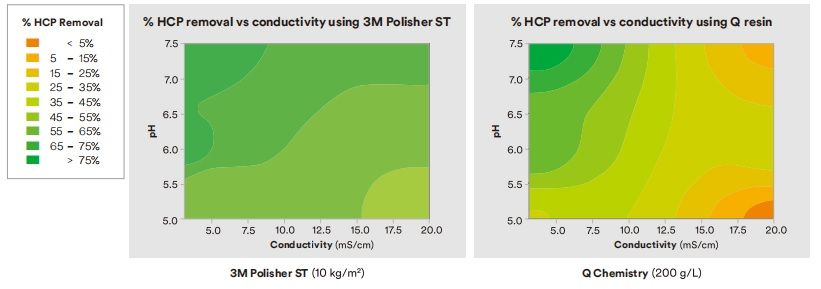

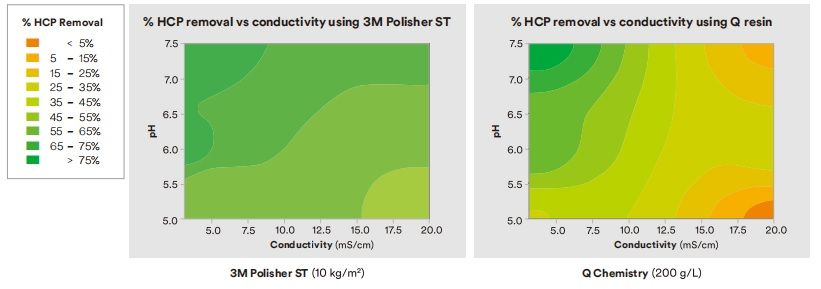

In comparison to Q column

In comparison to Q column

Polisher ST offers a combination of high dynamic antibody-loading (10kg/m²) capacities with low residence time (about 0.2 min compared to 1 minute for Q-resin), opening the way to an intensified high-productivity, truly single-use purification platform. Chromatographic columns have a limited loading capacity for polishing and virus capture. Furthermore, they are large and have a high investment cost.

Traditional column chromatography systems are slow in producing recombinant proteins.

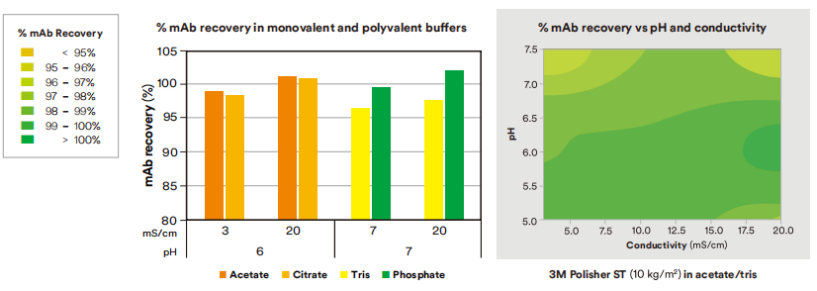

mAb recovery

mAb recovery

Without significant adjustments to pH and conductivity, Polisher ST has robust performance with respect to HCP and DNA clearance and better mAb recovery.

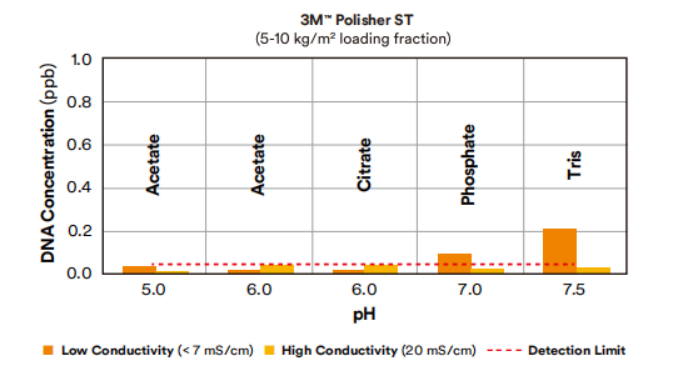

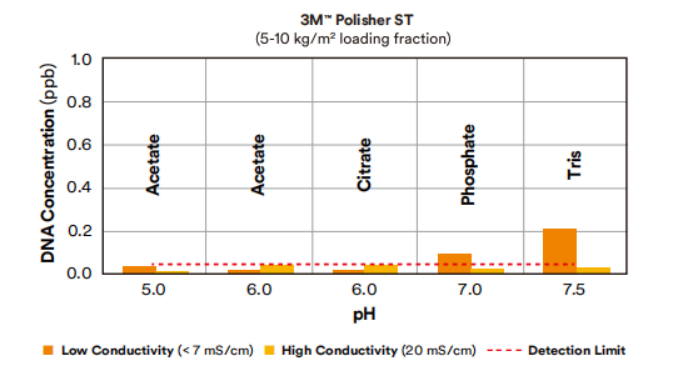

DNA reduction

DNA reduction

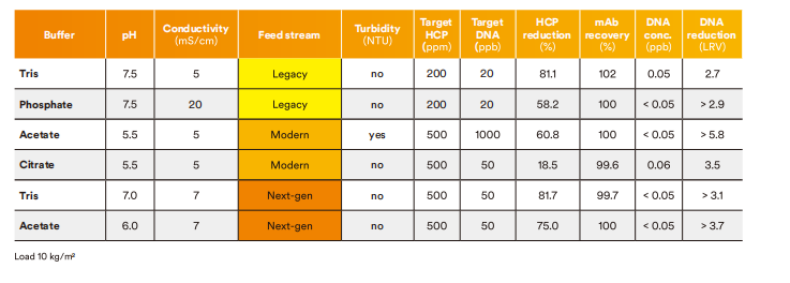

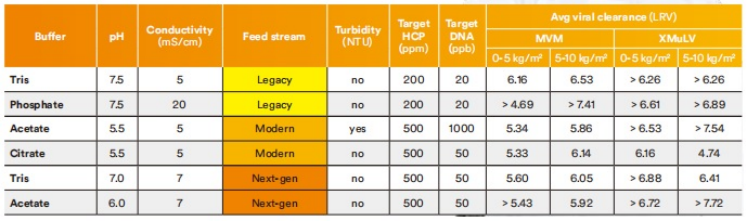

DNA clearance across a variety of initial concentrations (~10-1000 ppb) down to detection limit levels (0.05 ppb DNA) in all buffers (acetate, citrate, phosphate, tris) and conductivities were tested and are reported in the table below.

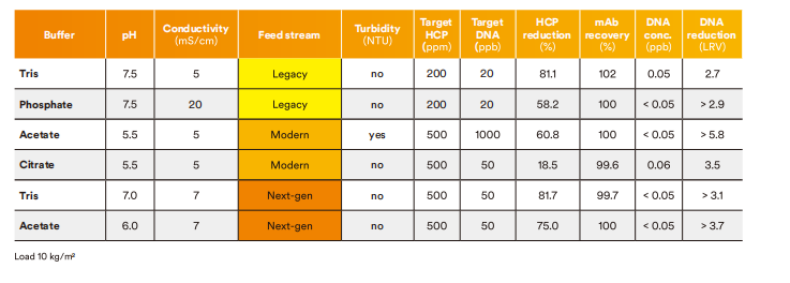

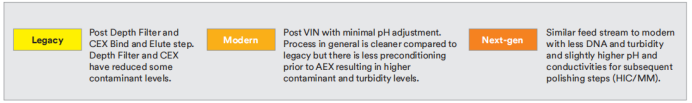

HCP and DNA reduction and mAb recovery in legacy, modern and next gen mAb feed

Performance in turbid streams

Performance in turbid streams

Polisher ST was challenged with turbid streams to simulate different downstream processes.

Similar HCP (> 50%) and DNA reduction (> 4 LRV) and mAb recovery (> 97%) compared to non-turbid samples. The ΔP across the capsule did not significantly change during the 10 kg/m2 load.

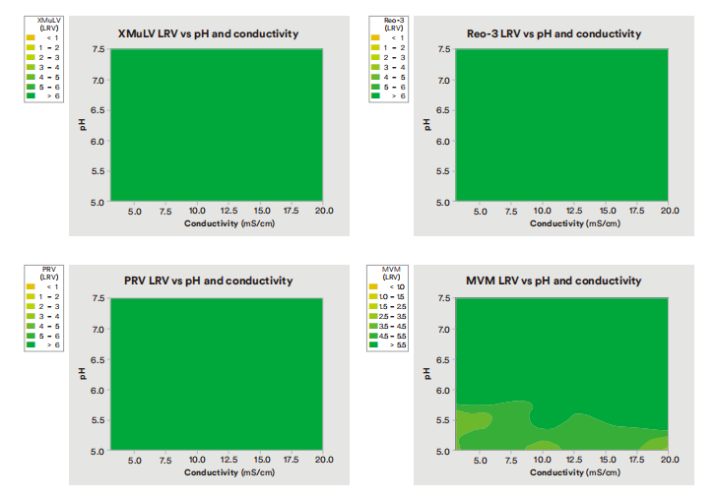

Viral Clearance in Buffer

Viruses XMuLV, Reo-3, PrV and MVM

XMuLV, Reo-3 and PrV all showed > 6 LRV clearance (detection limit) from pH 5-7.5, conductivities 3-20 mS/cm and in both monovalent (Acetate/Tris) and polyvalent (Citrate/Phosphate) buffers.

MVM showed > 4 LRV clearance from pH 5.5-7.5, conductivities 5-20 mS/cm and in both monovalent (Acetate/Tris) and polyvalent (Citrate/Phosphate) buffers.

Viral Clearance studies were performed with MVM and XMuLV using mAb solutions representing legacy, modern and next-gen mAb feed streams. The Tris pH 7.5, 5 mS/cm MVM study was performed at Charles River. All other studies were performed at Texcell.

3M™ Polisher ST is designed as a next generation bioprocessing solution to address the challenge biopharmaceutical companies have with the adoption of new manufacturing methods, for continued growth and innovation. Within the next five years, it is estimated that approximately 35% of today’s biologics will be manufactured using some sort of process intensification methods. Facilities will be smaller but capable of producing higher volumes of multiple molecules.

The key to this advancement will be the use of methods such as continuous bioprocessing technologies, some of which may be single use, which would enable facilities to reduce both their size and cycle times. The complexity of the bioprocessing industry has challenged companies’ innovation efforts, due to potential costs required for changes to take place.

Polisher ST is a single-use technology designed as a cost-efficient option to increase biomass production in therapeutic recombinant protein processes in all operating conditions and to replace downstream AEX polishing column in fed batch and/or continuous manufacturing.

3M Polisher ST is a compact, small footprint, higher capacity solution for delivering higher purity and yield in the downstream polishing unit operation in a connected continuous downstream operation for the flexible facility of the future.

Polisher ST enables a facility strategy that can overcome scale limitations and enable cost-efficient manufacturing to support the growing demand for biologics.

Guochu Technology (Xiamen) provides products of 3M, including: Polisher ST Series Chromatography Filter, Harvest RC Series Filter, Emphaze™ AEX Series Chromatography Filter, LifeASSURETM PDA Filter Cartridge, LifeASSURE™ PFS Filter Cartridge, LifeASSURE™ BDA Filter Cartridge, Zeta Plus™ Filter Cartridge, LifeASSURE™ BA Series Filter Cartridge, LifeASSURE™ BNA Filter Cartridge, BetafineT™ DP Filter Cartridge, BetafineT™ XL Filter Cartridge, BetafineT™ BT Filter Cartridge, Micro-Klean™ RT Filter Cartridge, Micro-Klean™ D Filter Cartridge, Betapure™ AU Filter Capsule, Betapure™ NT-T Filter Capsule, 3M™ High Flow Filter Cartridge, 3M™ NB Filter Bag, Micro Screen™ Metal Filter Cartridge, Liqui-Cel™ Membrane Contactor, Liqui Flux™ B Cross-flow Membrane, 3M™ CFSI Activated Carbon Filter Cartridge, ZW Series Cartridge, Zeta Plus™ Series Cartridge, Sanitary High Flow Cartridge, etc.

For details, please contact +86-592-6518670, +86-592-6514970.