Amino acid is the generic term for a class of organic compounds with amino and carboxyl groups, and more than 300 natural amino acids have been discovered, of which about 22 amino acids are needed by human bodies.

Amino acid is the basic unit for constituting proteins, and most amino acids are produced by fermentation. Fermentation broth is an extremely complex system containing microbial cells, metabolites and unconsumed media. The traditional process route includes centrifugation and plate and frame filter, but the filtrate quality is poor and soluble protein, carbohydrates, polypeptides, pigments and other impurities can’t be removed effectively. It increases the processing load of the subsequent processes and affects the overall yield of the extraction process and the final product quality; however, the traditional fixed bed resin process has large resin dosage, high consumption of acid and alkali water, high cost and great pressure on environmental protection. The process flow is shown in the following figure:

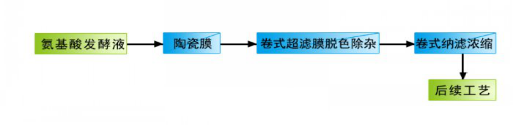

The ceramic membrane is used to replace the traditional centrifuge or plate frame to directly conduct filtration and clarification, remove protein, mycelium, suspended solids, colloid, bacteria and other organic substances, improve filtrate quality and reduce resin pollution in the later process; a continuous ion exchange system is used to replace the traditional fixed beds, save more than 50% of resin dosage, greatly reduce water consumption and acid and alkali consumption and achieve cleaner production; after decoloration, the feed liquid enters the nanofiltration membrane system again to carry out the concentration at low costs and reduce energy consumption, while it can remove some inorganic salts and reduce the ash content of products. The process flow is shown in the following figure:

Application in sterilization of glutamic acid fermentation broth:

Ceramic membrane is used for sterilization of glutamic acid fermentation broth, which can not only recycle procins, but also can reduce water amount in the process of departure significantly and reduce the sewage treatment load.

Contact:

Tel:+86 592 6514970

Email:market@guochukeji.com

Skype:18060902001

WhatsApp:18060902001

WeChat:18060902001

TM: guochukeji

QQ:1641011431